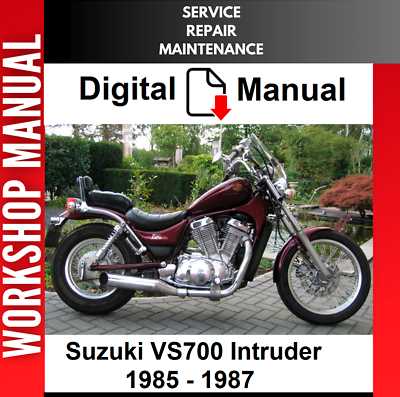

Complete Repair Guide for the 1986 Suzuki Intruder 700

Owning a vintage motorcycle is a rewarding experience, but it often comes with the responsibility of proper upkeep and maintenance. This guide serves as a comprehensive resource for enthusiasts looking to enhance their understanding of their beloved machines. From routine inspections to intricate repairs, having the right information can make a significant difference in the longevity and performance of these classic vehicles.

In this section, readers will discover essential insights into various aspects of motorcycle care. Each component, from the engine to the braking system, will be covered in detail, providing practical advice and techniques for effective maintenance. By following the recommended procedures, owners can ensure their rides remain in optimal condition, allowing for smooth journeys on the open road.

Moreover, this guide emphasizes the importance of understanding the unique characteristics of older models. Familiarity with specific components and systems not only aids in troubleshooting but also enhances the overall riding experience. Embracing the journey of preservation will enrich the connection between rider and machine, celebrating the history and craftsmanship of classic motorcycles.

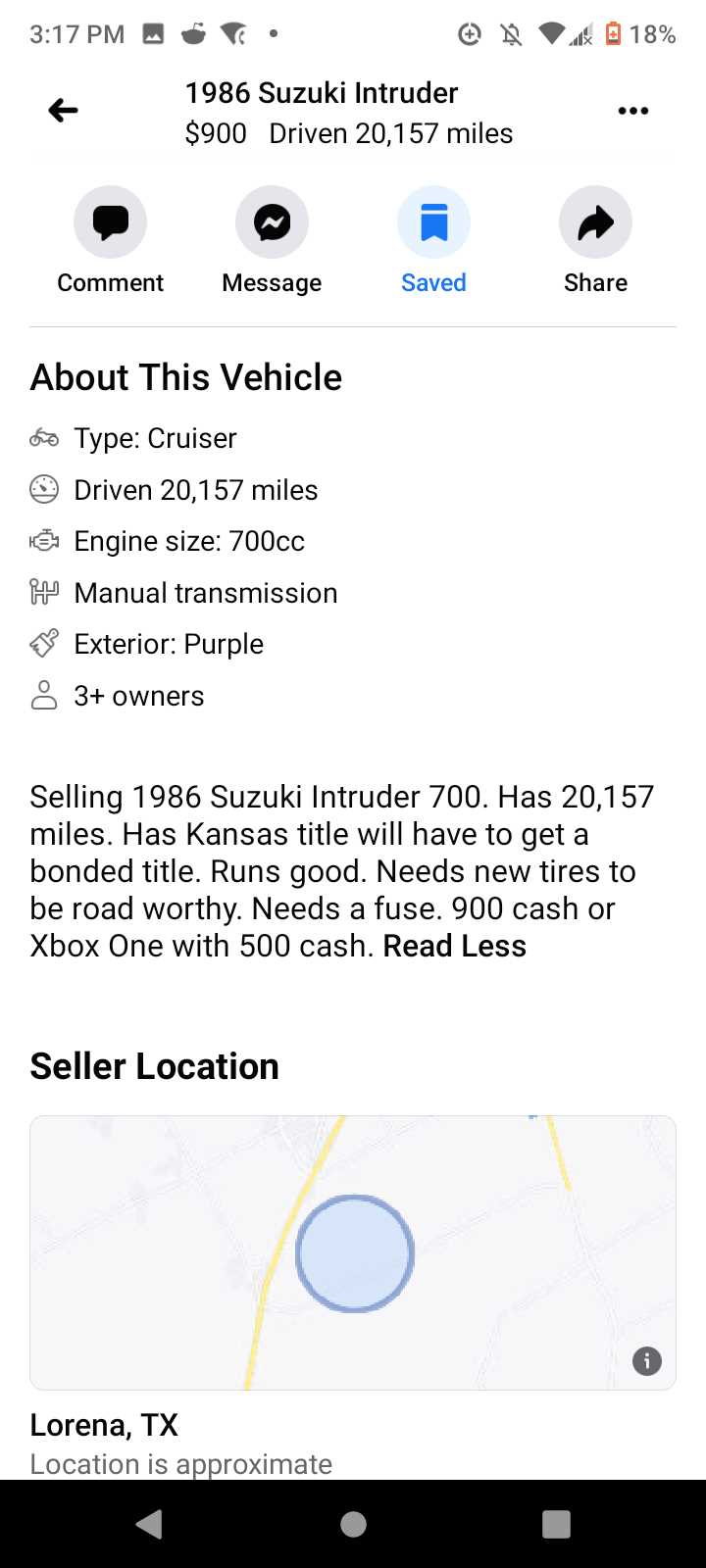

Overview of the 1986 Suzuki Intruder 700

This section provides a comprehensive look at a classic motorcycle known for its distinctive design and performance. Celebrated by enthusiasts, this model combines elegance with power, making it a remarkable choice for riders seeking both style and functionality.

Equipped with a robust engine, the machine offers an exhilarating riding experience. Its unique chassis design enhances stability and control, allowing for confident navigation on various terrains. Additionally, the incorporation of advanced features for its time contributed to a smoother ride, appealing to both casual riders and avid motorcyclists.

The aesthetic appeal is further complemented by its sleek lines and chrome accents, embodying the spirit of cruising. This model holds a special place in the hearts of motorcycle aficionados, representing an era where craftsmanship and performance were paramount.

In conclusion, this motorcycle stands out not only for its mechanical prowess but also for the rich riding experience it offers. Whether for daily commuting or weekend adventures, it remains a timeless choice that continues to attract attention on the road.

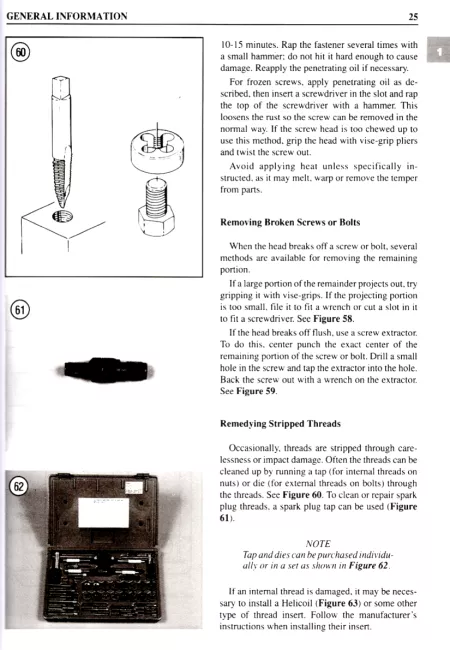

Essential Tools for Repairs

Having the right equipment is crucial when tackling maintenance tasks on your vehicle. Proper tools not only make the process smoother but also ensure that each component is handled with care, reducing the risk of damage. This section outlines the fundamental instruments necessary for efficient servicing.

Basic Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket types, is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers in various lengths will help in accessing hard-to-reach screws.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Specialized Instruments

- Multimeter: An essential tool for diagnosing electrical issues, measuring voltage, current, and resistance.

- Feeler Gauges: Useful for measuring gaps in components, especially in valve adjustments.

- Chain Breaker: Necessary for servicing the drive chain, allowing for easy removal and installation.

- Oil Filter Wrench: Helps in removing and installing oil filters without damage.

Engine Maintenance Procedures

Proper upkeep of the power unit is crucial for ensuring optimal performance and longevity. Regular attention to various components not only enhances reliability but also contributes to a smoother riding experience. This section outlines essential practices to keep the engine in top condition.

Begin with routine oil changes, as clean lubricant is vital for reducing friction and preventing wear. Follow the manufacturer’s guidelines for the appropriate type and viscosity. Inspect the oil filter regularly and replace it as needed to maintain effective filtration.

Next, check the cooling system to prevent overheating. Ensure that the coolant level is adequate and that there are no leaks. Cleaning the radiator and ensuring proper airflow can also enhance cooling efficiency.

Fuel system maintenance is another critical aspect. Regularly inspect fuel lines for cracks or leaks, and clean the fuel filter to ensure uninterrupted flow. Consider using fuel additives to maintain injector cleanliness and enhance combustion.

Lastly, periodic inspections of the ignition system are essential. Replace worn spark plugs and check the ignition timing to ensure efficient engine operation. Keeping the electrical connections clean and secure will also prevent misfires and performance issues.

Transmission Inspection Guidelines

Regular examination of the transmission system is essential for maintaining optimal performance and preventing costly repairs. Understanding the key components and identifying potential issues early can enhance the longevity and reliability of the vehicle.

Key Components to Inspect

- Gears: Check for wear or damage, ensuring smooth engagement during operation.

- Bearings: Inspect for any signs of wear that could affect performance.

- Seals: Look for leaks or degradation that could compromise fluid retention.

- Fluid Condition: Examine the transmission fluid for contamination or discoloration.

Inspection Process

- Start with a visual inspection of the transmission case for any obvious leaks or damage.

- Check fluid levels and condition, replacing if necessary.

- Test the shifting mechanism, ensuring it operates smoothly without excessive resistance.

- Perform a road test to listen for unusual noises or vibrations that may indicate underlying issues.

Electrical System Troubleshooting

This section focuses on diagnosing issues within the electrical framework of the vehicle, a crucial aspect of ensuring optimal performance. Identifying and resolving electrical faults can significantly enhance reliability and safety.

Initial Checks: Begin by examining the battery for proper voltage levels and secure connections. A depleted or poorly connected battery can lead to a range of operational problems.

Wiring Inspection: Carefully inspect all wiring for signs of wear, corrosion, or damage. Faulty wires can disrupt current flow and lead to intermittent issues that are challenging to diagnose.

Component Testing: Utilize a multimeter to test individual components, such as fuses, switches, and relays. This can help pinpoint malfunctioning parts that may be affecting the overall system.

Ground Connections: Ensure all ground connections are clean and tight. Poor grounding can result in erratic behavior and is often overlooked during troubleshooting.

Continuity Checks: Perform continuity tests on circuits to verify that electrical paths are intact. Breaks in the circuit can cause critical components to fail.

By systematically addressing each element of the electrical system, one can effectively diagnose and rectify issues, ensuring the vehicle operates smoothly and reliably.

Brake System Servicing Tips

Maintaining the braking mechanism is crucial for ensuring safety and optimal performance. Proper care and attention can significantly enhance the lifespan of components while preventing potential failures. Regular checks and adjustments are essential in preserving the reliability of the system.

Regular Inspections

Conduct thorough examinations of the braking parts, including pads, rotors, and calipers. Look for signs of wear or damage. If the pads appear thin or unevenly worn, it may be time for replacement. Inspecting fluid levels and quality is also vital; replace any contaminated or old fluid to maintain responsiveness.

Cleaning and Lubrication

Ensure all components are free from dirt and debris. Use appropriate cleaning agents to remove grime from pads and rotors. Additionally, apply lubricant to the caliper slides and contact points to facilitate smooth operation. This simple maintenance step can prevent sticking and enhance overall functionality.

By following these practices, you can ensure a safer and more efficient braking experience.

Suspension Adjustment Techniques

Properly tuning the suspension is crucial for optimizing performance and enhancing ride quality. The adjustments can greatly influence handling characteristics, stability, and comfort. Understanding various techniques allows for tailored settings that match personal preferences and riding conditions.

Preload Adjustment

Adjusting the preload modifies the initial tension in the suspension springs. This setting impacts ride height and affects how the bike responds to bumps and dips in the road. Increasing preload raises the ride height, which can improve cornering clearance and reduce bottoming out. Conversely, reducing preload can lower the ride height, enhancing comfort during casual rides.

Damping Settings

Fine-tuning the damping settings controls the speed at which the suspension compresses and rebounds. Adjusting compression damping affects how the suspension reacts to bumps, while rebound damping influences how quickly it returns to its original position. Finding the right balance between these settings ensures that the suspension responds appropriately to varied terrains, providing both stability and comfort during the ride.

Wheel and Tire Care

Proper maintenance of wheels and tires is essential for optimal performance and safety. Regular attention to these components can enhance handling, increase longevity, and improve overall riding experience. This section provides guidance on effective care practices to ensure your vehicle remains in top condition.

To maintain wheels and tires effectively, consider the following steps:

- Regular Inspection: Check for signs of wear, such as cracks, bulges, or uneven tread wear. Inspect the sidewalls for any damage or foreign objects.

- Proper Inflation: Maintain correct tire pressure as recommended by the manufacturer. Under-inflation can lead to poor handling, while over-inflation can cause premature wear.

- Cleaning: Clean wheels regularly to remove dirt, grime, and brake dust. Use appropriate cleaners to avoid damaging the finish.

- Tread Depth Monitoring: Ensure the tread depth meets safety standards. Use a tread depth gauge to monitor wear and replace tires when necessary.

- Alignment and Balancing: Regularly check wheel alignment and balance to prevent uneven wear and ensure smooth handling.

- Rotation: Rotate tires according to the vehicle’s maintenance schedule to promote even wear across all tires.

By following these guidelines, you can enhance the performance and longevity of your wheels and tires, ensuring a safe and enjoyable riding experience.

Fuel System Cleaning Steps

Maintaining the efficiency of a vehicle’s fuel delivery mechanism is crucial for optimal performance. Regular cleaning of this system helps prevent issues such as clogging and poor combustion, ensuring smooth operation. Below are the essential steps to effectively clean the fuel system.

Preparation

- Gather necessary tools: wrenches, a fuel line disconnect tool, and a cleaning solution.

- Ensure safety: work in a well-ventilated area and wear protective gloves and eyewear.

- Disconnect the battery to prevent electrical hazards.

Cleaning Process

- Remove the fuel tank: carefully detach the fuel tank from the frame.

- Drain old fuel: ensure all residual fuel is emptied from the tank.

- Inspect fuel filter: replace the filter if it shows signs of clogging or wear.

- Flush the fuel lines: use a cleaning solution to thoroughly flush out any debris or buildup.

- Clean injectors: utilize an injector cleaning kit to restore proper flow and function.

- Reassemble the system: carefully reconnect all components, ensuring secure fittings.

- Refill with fresh fuel: use high-quality fuel to enhance performance.

Following these steps can significantly improve the performance and longevity of the fuel delivery system, ensuring a reliable ride.

Bodywork Repair Essentials

Maintaining the exterior of your vehicle is crucial for both aesthetics and functionality. This section focuses on the fundamental aspects of restoring and preserving the body of your motorcycle. Understanding how to address common issues can enhance its appearance and longevity.

Assessment of Damage: Start by thoroughly inspecting the bodywork for any dents, scratches, or corrosion. Identifying the extent of the damage is essential for determining the appropriate methods and materials needed for restoration.

Cleaning: Before any repair work, ensure that the surface is clean. Use a gentle cleaner to remove dirt, grime, and any previous wax or polish. This step is vital for achieving a smooth finish when applying touch-up paint or sealants.

Repair Techniques: For minor dents, tools such as a suction cup or a dent puller can be effective. In cases of scratches, sanding and filling may be necessary. Choose suitable fillers and ensure they match the original texture of the bodywork for seamless integration.

Painting: After repairs, the next step is painting. Select high-quality paint that matches the original color of the vehicle. Apply multiple thin coats to achieve an even finish, allowing adequate drying time between applications.

Finishing Touches: Once the paint is dry, consider applying a protective coat. This not only enhances the gloss but also provides a barrier against environmental factors. Regular maintenance of the exterior will keep the motorcycle looking great and protect it from future damage.

Recommended Replacement Parts

Ensuring optimal performance and longevity of your motorcycle involves selecting high-quality components. This section provides insights into essential parts that may require attention or replacement during maintenance to keep your ride smooth and efficient.

- Air Filter: A clean air filter enhances engine efficiency and improves fuel economy.

- Oil Filter: Regular replacement of the oil filter helps maintain engine health and performance.

- Brake Pads: Fresh brake pads ensure safe stopping power and enhance rider confidence.

- Tires: Quality tires improve handling and traction, essential for safe riding.

- Battery: A reliable battery is crucial for starting and powering electrical systems.

Consider these components during your maintenance routine to ensure your machine operates at its best. Investing in quality replacements can lead to significant improvements in overall performance and safety.

Safety Considerations During Repairs

When undertaking maintenance tasks, ensuring personal safety is paramount. It is essential to approach the process with caution, understanding the potential hazards involved. By adhering to recommended precautions, one can minimize risks and create a secure working environment.

Protective Gear

Wearing appropriate protective equipment is crucial. This includes gloves to safeguard hands from sharp objects and chemicals, goggles to protect eyes from debris, and a mask to avoid inhaling harmful fumes. Always prioritize your health and safety by ensuring you are equipped for the job at hand.

Workspace Organization

A well-organized workspace significantly contributes to safety. Keep tools and materials neatly arranged to avoid tripping hazards and ensure easy access. Clear any unnecessary items from the area, and make sure to have a fire extinguisher nearby in case of emergencies. By maintaining order, you can focus on the task without distractions, enhancing both efficiency and safety.