Suzuki Aerio Repair Guide

This section offers an extensive overview of essential practices for maintaining your automobile. By understanding the various components and systems within the vehicle, you can ensure optimal performance and longevity.

Familiarity with common issues and their resolutions is crucial for any vehicle owner. This guide provides insights into troubleshooting, preventive measures, and step-by-step processes to address various concerns effectively.

With detailed explanations and tips, you will be equipped to handle maintenance tasks confidently. Whether you are a novice or have some experience, this resource aims to enhance your understanding and skills in vehicle upkeep.

Common Issues with Suzuki Aerio

Vehicle owners often encounter a range of challenges that can affect performance and reliability. Identifying these frequent problems can help in maintaining optimal function and ensuring longevity.

Engine Performance Concerns

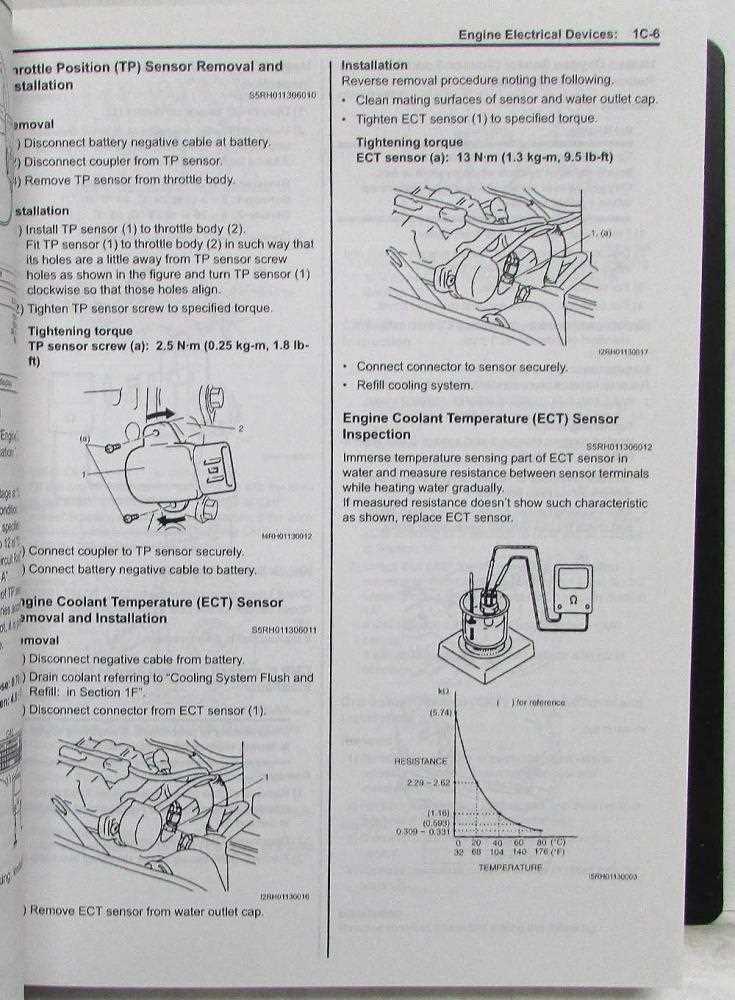

Issues related to engine performance are prevalent, often manifesting as reduced power or unusual noises. Regular inspections can aid in detecting underlying faults early.

Electrical System Failures

Malfunctions in the electrical system can lead to various complications, including problems with starting or battery drainage. Ensuring proper connections and timely replacements can mitigate these issues.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving issues that may arise in your vehicle. Following these steps will help you diagnose problems efficiently and effectively.

Identify the Symptoms

Begin by noting any unusual behaviors or warning signs. Understanding the symptoms will guide your troubleshooting process.

- Engine not starting

- Unusual noises

- Warning lights on the dashboard

- Poor fuel efficiency

Basic Checks

Before diving deeper, conduct a few basic checks to eliminate common problems.

- Inspect the battery for corrosion and ensure it is fully charged.

- Check the fuel level and confirm that fuel is reaching the engine.

- Examine the oil level and condition.

- Review the condition of the tires and brakes.

Engine Maintenance Tips for Aerio

Proper care and upkeep of the power unit are essential for optimal performance and longevity. Regular attention to key components can prevent issues and enhance driving experience.

1. Regular Oil Changes: Frequent oil changes are crucial to ensure that the engine runs smoothly. Always use the recommended type of lubricant and adhere to the service intervals specified in the documentation.

2. Check Fluid Levels: Regularly inspect and top up essential fluids, such as coolant and transmission fluid. Maintaining appropriate levels prevents overheating and enhances functionality.

3. Air Filter Replacement: The air filter should be examined and replaced as needed. A clean filter ensures proper airflow, contributing to better fuel efficiency and engine health.

4. Spark Plug Inspection: Inspecting and replacing spark plugs at recommended intervals can prevent misfires and improve fuel efficiency. Ensure proper gap settings for optimal performance.

5. Timing Belt Maintenance: Check the timing belt for wear and replace it according to the manufacturer’s schedule. A worn belt can lead to serious engine damage if it fails.

Following these guidelines will help maintain the efficiency and reliability of the engine, ensuring a smoother and more enjoyable driving experience.

Understanding the Electrical System

The electrical system of a vehicle is essential for its operation, playing a crucial role in powering various components. It includes elements that provide energy to the engine, lights, and other electronic features, ensuring optimal performance and safety.

Key Components of the Electrical System

This system comprises several vital parts that work together seamlessly. Understanding each component’s function helps in diagnosing issues and maintaining efficiency.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting the engine and powering electrical accessories. |

| Alternator | Generates electricity while the engine is running, recharging the battery. |

| Starter Motor | Cranks the engine to initiate combustion. |

| Fuses | Protect electrical circuits by preventing overloads. |

Troubleshooting Common Issues

Identifying problems within the electrical system can prevent more significant malfunctions. Regular checks of the battery condition, wiring integrity, and connections can help maintain reliability.

Transmission Problems and Solutions

Issues with the gear shifting mechanism can significantly impact vehicle performance. Recognizing common symptoms early can help prevent more severe complications and costly repairs. This section addresses typical transmission troubles and practical solutions to resolve them effectively.

Common Symptoms

Drivers may experience a range of issues, including difficulty in changing gears, unusual noises during operation, or slipping sensations while driving. These signs often indicate underlying problems within the transmission system that require prompt attention.

Diagnostic and Repair Steps

To address these concerns, start with a thorough inspection of the fluid levels and condition. Low or contaminated fluid can lead to malfunctioning components. If necessary, change the transmission fluid and replace the filter. If issues persist, further diagnostics may be needed, potentially involving a professional technician to evaluate more complex internal components.

Braking System Inspection Procedures

Regular examination of the braking mechanism is crucial for ensuring optimal performance and safety. This process involves assessing various components to identify any signs of wear or malfunction that may compromise the effectiveness of the system.

1. Visual Inspection: Begin by inspecting the brake pads and rotors for signs of damage or excessive wear. Look for uneven wear patterns, cracks, or overheating discoloration. Ensure that all components are securely attached and free of corrosion.

2. Fluid Check: Examine the brake fluid reservoir for proper fluid level and condition. If the fluid appears murky or contaminated, it may require replacement. Always use the manufacturer-recommended type of fluid.

3. Test Brake Operation: Conduct a test drive to evaluate the responsiveness of the brakes. Pay attention to any unusual noises, vibrations, or pulling to one side. These symptoms can indicate underlying issues that need addressing.

4. Professional Evaluation: If any irregularities are detected during your inspection, consult a qualified technician for a comprehensive assessment. Professional expertise can help ensure that all aspects of the braking system are functioning correctly.

Suspension and Steering Repairs

This section covers the essential aspects of maintaining and restoring the suspension and steering systems of your vehicle. Proper functioning of these components is crucial for safety, comfort, and overall performance on the road. Regular checks and timely interventions can prevent more significant issues and enhance driving experience.

Common Issues and Solutions

Frequent problems include worn-out bushings, damaged struts, and misaligned wheels. Addressing these issues involves thorough inspections and replacement of faulty parts. Ensuring proper alignment is vital to prevent uneven tire wear and improve handling.

Maintenance Tips

Regularly inspect your vehicle’s suspension and steering components for signs of wear. Lubrication of moving parts can extend their lifespan. Additionally, adhering to the manufacturer’s recommendations for maintenance intervals will help maintain optimal performance.

Bodywork and Paint Restoration Techniques

Restoring the exterior of a vehicle involves a series of methods aimed at enhancing its aesthetic appeal and protecting it from environmental damage. This process not only rejuvenates the appearance but also contributes to the longevity of the vehicle’s structure.

Preparation Steps

Before any restoration work begins, it is crucial to prepare the surface properly. This includes:

- Washing the vehicle to remove dirt and debris.

- Inspecting for dents, scratches, and rust spots.

- Sanding the affected areas to create a smooth base.

Painting Techniques

Once the preparation is complete, the painting phase can commence. Key techniques include:

- Using primer to ensure better adhesion of the paint.

- Applying base coat in thin, even layers.

- Finishing with a clear coat for added protection and shine.

Cooling System Maintenance Essentials

Proper upkeep of the cooling mechanism is crucial for the longevity and efficiency of any vehicle. Regular checks and maintenance can prevent overheating and ensure optimal performance, safeguarding against potential engine damage.

Key aspects of cooling system care include inspecting fluid levels, checking for leaks, and ensuring that the radiator and hoses are in good condition. By following a routine maintenance schedule, drivers can avoid costly repairs down the line.

| Task | Frequency | Notes |

|---|---|---|

| Check coolant level | Monthly | Top off if necessary |

| Inspect hoses | Every 6 months | Look for cracks or leaks |

| Flush coolant system | Every 2 years | Replace old fluid to prevent corrosion |

| Test thermostat | As needed | Replace if malfunctioning |

Replacing Filters and Fluids Efficiently

Maintaining optimal performance in your vehicle involves regular replacement of essential components such as filters and fluids. This process ensures that the engine and other systems operate smoothly and efficiently, prolonging the lifespan of the vehicle.

Here are key steps for effective replacement:

- Gather necessary tools and materials:

- New filters (oil, air, fuel)

- Recommended fluids (engine oil, coolant, brake fluid)

- Wrenches and screwdrivers

- Drain pan for old fluids

- Locate the oil filter and use the wrench to remove it.

- Clean the mounting surface before installing the new filter.

- Fill the new filter with oil before installation.

- Open the air intake housing.

- Remove the old filter and clean the housing.

- Insert the new air filter, ensuring a snug fit.

- Depressurize the fuel system as needed.

- Disconnect fuel lines carefully to avoid spills.

- Install the new filter and reconnect the lines securely.

- Drain old fluids using a drain pan.

- Refill with new fluids, checking levels as you go.

By following these steps, you ensure that your vehicle remains in peak condition, enhancing both safety and efficiency on the road.