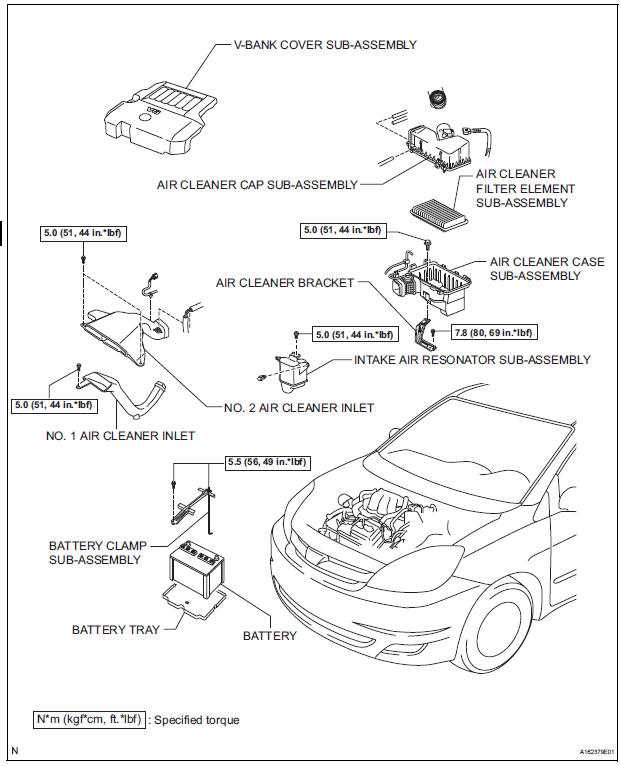

Comprehensive Guide for 2005 Toyota Sienna Repairs

This section provides an extensive overview for owners seeking detailed guidance on the upkeep of their minivan. Understanding the various components and systems is essential for ensuring longevity and optimal performance.

From engine specifications to troubleshooting common issues, this resource is designed to assist drivers in navigating maintenance tasks effectively. Utilizing this information can enhance driving experience and reduce the likelihood of unexpected repairs.

Regular check-ups and timely interventions can significantly extend the life of the vehicle. Emphasizing preventive measures and routine inspections fosters a proactive approach to vehicle care.

Equipping oneself with the right knowledge empowers vehicle owners to make informed decisions regarding service and maintenance. A well-maintained minivan not only ensures safety but also contributes to overall satisfaction on the road.

The suspension system is crucial for maintaining vehicle stability and ride comfort. Regular examination of its components can prevent potential issues that affect safety and performance. This guide outlines essential steps for a thorough inspection, ensuring the system operates efficiently.

Visual Inspection

Begin with a comprehensive visual assessment of the suspension parts. Look for:

- Cracks or damage on the control arms

- Worn bushings that may exhibit signs of degradation

- Leaking shocks or struts

- Misalignment of wheels and components

Component Testing

Once the visual inspection is complete, proceed with testing individual components:

- Check the shock absorbers for fluid leakage.

- Test the springs for signs of sagging or breakage.

- Examine the alignment by measuring tire wear patterns.

- Evaluate the sway bar links for any play or movement.

Brake System Repair Procedures

This section outlines essential steps for addressing issues within the braking mechanism of a vehicle. Proper maintenance and repair techniques are crucial for ensuring safety and optimal performance. It is important to follow guidelines closely to achieve effective results.

Inspection and Assessment

Begin by thoroughly inspecting the brake components. Look for wear signs, leaks, or damage. A detailed assessment helps identify necessary actions and parts needing replacement. Pay attention to the following elements:

| Component | Inspection Criteria |

|---|---|

| Brake Pads | Check for thickness and even wear |

| Brake Rotors | Inspect for warping or scoring |

| Brake Lines | Look for leaks and corrosion |

Replacement Procedures

If any components are found to be defective, follow the replacement procedures carefully. Ensure all new parts are compatible and follow manufacturer specifications. Begin with the disassembly of the worn components, and proceed to install the new parts, ensuring proper alignment and secure connections.

Heating and Cooling System Issues

The heating and cooling system in vehicles plays a crucial role in maintaining comfort and safety. When problems arise within this system, they can lead to discomfort for passengers and compromise visibility during adverse weather conditions. Identifying and addressing these issues promptly is essential for optimal performance.

Common Symptoms: Drivers may notice inconsistent temperature regulation, unusual noises, or strange odors emanating from the vents. Additionally, insufficient airflow can indicate potential blockages or mechanical failures.

Potential Causes: Issues can stem from various sources, including refrigerant leaks, malfunctioning thermostats, or faulty blower motors. Regular maintenance checks can help identify and mitigate these problems before they escalate.

Addressing heating and cooling system concerns early can prevent more extensive repairs and ensure a pleasant driving experience.

Fluid Replacement and Maintenance

Regular upkeep of essential liquids is crucial for the optimal functioning of any vehicle. This section emphasizes the significance of timely fluid changes and the maintenance practices required to ensure long-lasting performance and reliability.

Importance of Timely Fluid Changes

Over time, automotive fluids can degrade, leading to potential damage and reduced efficiency. Engine oil, for example, loses its viscosity and ability to lubricate effectively, making it essential to replace it periodically. Transmission fluid and coolant also require regular monitoring and replacement to prevent overheating and mechanical failures.

Routine Maintenance Practices

In addition to fluid replacement, performing routine checks can help identify issues before they escalate. Regularly inspecting fluid levels and conditions ensures that any necessary adjustments are made promptly. Using high-quality replacements tailored for your vehicle can further enhance performance and longevity.

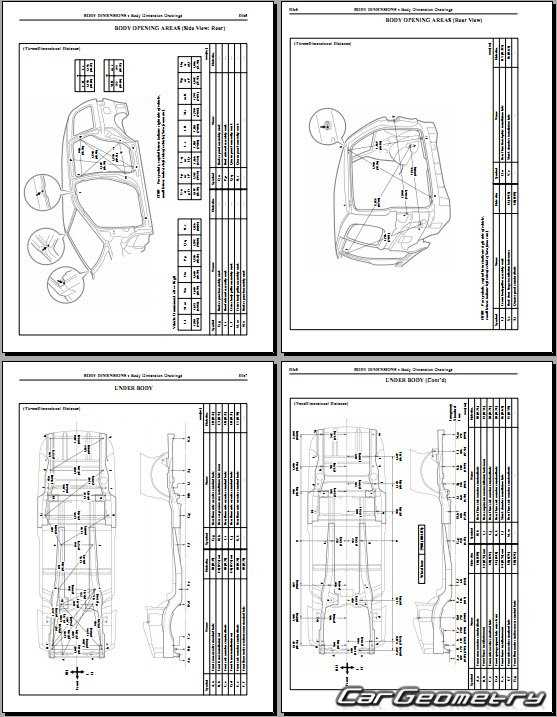

Bodywork and Interior Repairs

This section focuses on the various aspects of external and internal modifications and maintenance required to keep a vehicle in optimal condition. Attention to detail is crucial in ensuring longevity and aesthetic appeal.

Exterior Adjustments

Maintaining the body of a vehicle involves several key procedures:

- Inspect for dents and scratches regularly.

- Address rust spots promptly to prevent further damage.

- Ensure proper alignment of doors and panels.

- Apply protective coatings for longevity.

Interior Maintenance

For a comfortable driving experience, the interior must be well cared for. Consider the following tasks:

- Clean upholstery and carpets regularly.

- Check and replace worn-out seat covers.

- Ensure all dashboard components are functioning correctly.

- Install new mats for added protection against dirt.

Routine Checkup and Diagnostics

Regular maintenance and assessment are crucial for ensuring the longevity and efficiency of your vehicle. Implementing a systematic approach to monitoring various components can prevent unexpected issues and enhance overall performance.

Key Areas for Inspection

- Fluid Levels: Check oil, coolant, brake, and transmission fluids for proper levels and condition.

- Tire Condition: Inspect tread depth, inflation pressure, and overall wear.

- Brake System: Examine pads, rotors, and brake fluid for signs of wear or leaks.

- Battery Health: Assess battery charge and check for corrosion on terminals.

- Lights and Signals: Ensure all exterior and interior lights function correctly.

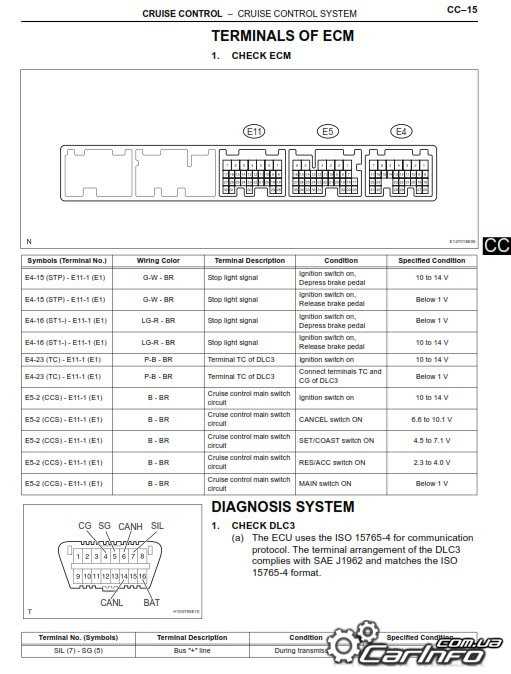

Diagnostic Procedures

- Utilize a diagnostic tool to retrieve error codes from the onboard computer.

- Inspect the engine and transmission systems for any unusual noises or performance issues.

- Check for leaks in fuel and exhaust systems.

- Monitor emissions levels to ensure compliance with regulations.

Conducting these regular assessments not only helps in maintaining optimal functionality but also in identifying potential problems early on, saving time and resources in the long run.

Safety Features and Troubleshooting

This section focuses on the essential protective elements present in vehicles and the common issues that may arise. Understanding these features not only enhances safety but also assists in identifying potential problems that can affect performance and reliability.

Key Safety Features

Modern vehicles are equipped with various safety systems designed to protect occupants during a collision. Airbags, anti-lock braking systems, and electronic stability control are among the crucial components that contribute to overall safety. These technologies work together to minimize the risk of accidents and reduce the severity of injuries.

Troubleshooting Common Issues

When encountering issues related to safety features, it’s important to conduct a thorough inspection. For instance, if warning lights appear on the dashboard, this may indicate a malfunction within the safety systems. Regular maintenance and prompt attention to warning signals can prevent complications and ensure the vehicle remains safe for all users.

Finding OEM Parts for Repairs

Locating original equipment manufacturer components is crucial for maintaining vehicle performance and reliability. These parts are designed specifically for your vehicle, ensuring compatibility and longevity.

Here are some effective strategies for sourcing OEM components:

- Authorized Dealerships: Visit local dealerships that offer parts for your vehicle brand. They typically stock a comprehensive range of OEM items.

- Online Retailers: Utilize reputable online platforms that specialize in automotive parts. Look for websites that guarantee genuine products.

- Auto Parts Stores: Check local auto parts stores that may carry OEM options or can order them for you.

- Manufacturer Websites: Explore the manufacturer’s official website for direct purchases or to find authorized distributors.

- Forums and Communities: Join online forums dedicated to your vehicle type. Members often share recommendations for reliable sources.

By exploring these avenues, you can ensure that the components you purchase meet the necessary quality standards for effective maintenance.

Step-by-Step Repair Techniques

This section provides a comprehensive guide to effective methods for addressing various issues in vehicles. By following a structured approach, you can enhance your skills and ensure successful outcomes in your automotive tasks.

Essential Tools and Equipment

- Wrenches and Sockets

- Jack and Stands

- Diagnostic Scanner

- Safety Gear

Basic Procedures to Follow

- Identify the Problem: Thoroughly inspect the vehicle to determine the source of the issue.

- Gather Necessary Tools: Assemble all required equipment before starting the work.

- Follow Safety Protocols: Ensure proper safety measures are in place, including protective gear.

- Execute the Repair: Carefully carry out the steps needed to fix the problem, following guidelines.

- Test Functionality: After completion, verify that the repairs have resolved the issue effectively.