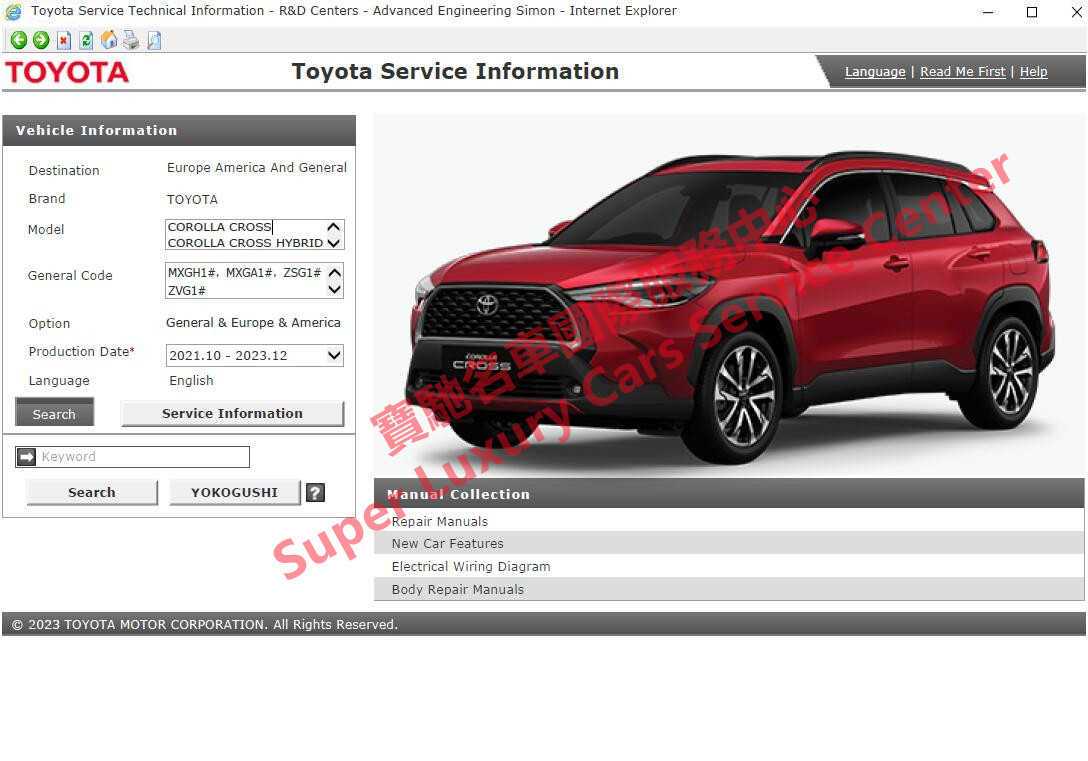

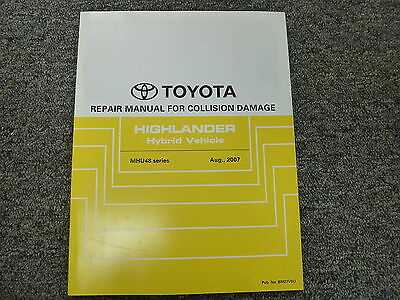

2008 Toyota Highlander Hybrid Repair Guide

Ensuring the optimal performance of a vehicle requires a detailed understanding of its components and systems. Regular upkeep and a systematic approach to servicing can significantly extend the lifespan of various parts, while also helping to avoid costly issues down the road. This guide offers in-depth insights tailored to enhancing functionality and addressing common technical needs.

Designed to cater to a wide range of essential tasks, this resource is ideal for both newcomers to vehicle upkeep and seasoned enthusiasts. Step-by-step instructions and practical tips cover everything from routine checks to more complex procedures, ensuring clarity in every aspect of the process. With this resource, vehicle owners can confidently maintain and troubleshoot various systems independently.

Each section is crafted with a focus on accessibility and practical knowledge, emphasizing the importance of regular inspections and proactive care. By following these guidelines, users can expect to maintain reliable performance and a high standard of safety, ensuring their vehicle remains dependable over time.

2008 Toyota Highlander Hybrid Repair Manual

Guiding users through efficient methods for upkeep and troubleshooting, this section provides insights into maintaining the vehicle’s complex systems, including both engine and electronic components. Recognizing the vehicle’s specific configurations, the manual helps ensure dependable performance over time by detailing essential procedures for servicing its unique features.

| Component | Function | Maintenance Tips |

|---|---|---|

| Electrical Systems | Manages energy flow and battery stability | Check connections and clean terminals regularly |

| Cooling Mechanism | Prevents overheating during extended operation | Inspect fluid levels and radiator function periodically |

| Drive System | Enables efficient energy distribution and power | Ensure smooth transitions between power sources |

| Battery Management | Monitors and adjusts power flow | Test voltage output and replace damaged connections |

| Braking System | Maintains control during regenerative braking | Inspect pad wear and check for smooth engagement |

Essential Maintenance for Longevity

Regular upkeep is crucial to ensure any vehicle remains efficient and reliable over the years. Consistent attention to various components can prevent unexpected breakdowns and extend the overall lifespan. This section outlines critical practices that contribute to durability and optimal performance.

Routine Fluid Checks: Monitoring fluid levels, including coolant, brake, and transmission fluids, is essential for smooth operation. These fluids not only support functionality but also protect internal components from wear, making regular inspection a priority.

Brake System Care: Inspecting the brake system frequently ensures safe driving and quick response times. Regularly replacing brake pads, cleaning components, and checking for wear or leaks helps maintain braking efficiency and reduces the risk of costly repairs.

Tire Maintenance: Proper tire care is essential for both safety and fuel economy. Rotating tires, checking for proper alignment, and maintaining correct pressure ensure a balanced ride and even wear, preventing early tire replacement.

Battery Health: A well-maintained battery is fundamental for dependable starts and uninterrupted electrical functions. Regularly cleaning terminals, checking voltage, and securing connections can prevent unexpected power issues.

Air Filter Replacement: A clean air filter supports efficient engine performance by ensuring proper air intake. Replacing it at recommended intervals reduces strain on the engine, enhancing fuel efficiency and overall driving experience.

By implementing these maintenance practices, owners can expect enhanced reliability and durability from their vehicles, ultimately reducing long-term expenses and preserving performance.

Battery Troubleshooting and Replacement Guide

Efficient power management is crucial for the optimal performance of any system. In this section, we’ll explore ways to identify and resolve common issues that can arise with power sources, as well as steps to replace a failing unit. Proper diagnosis and understanding of the signs of malfunction are key to maintaining efficiency and preventing unexpected breakdowns.

Common Symptoms of Battery Issues

Signs of a declining power unit often include inconsistent performance, unusual sounds, or dashboard alerts. In addition, a noticeable drop in power, difficulty starting, and irregular charge cycles may signal that the unit needs attention. Recognizing these symptoms early can help prevent further damage.

Step-by-Step Troubleshooting Process

To begin troubleshooting, start by checking the unit’s physical connections for looseness or corrosion, as these are common sources of problems. Next, measure the voltage output using a multimeter to determine if it meets standard levels. If the output is below the expected range, the power source may require replacement. Ensure the connections are clean and secure to maintain a stable power flow.

Removing and Replacing the Power Source

Before replacement, disconnect the power supply and ensure all connections are safely isolated. Carefully remove the old unit, noting the exact alignment and connectors used. When installing a new power source, align it precisely with the connectors and secure all fasteners to prevent movement. Once installed, test the output to confirm that it functions correctly.

Testing After Installation

After replacement, it’s essential to verify the stability of the new unit. Run the system for a few cycles, monitoring for any warnings or irregularities. Consistent operation without alerts typically confirms a successful installation. Periodic testing can also help identify potential issues before they affect the system’s performance.

Hybrid System Diagnostics and Solutions

In advanced automotive systems, diagnosing energy-efficient propulsion mechanisms requires a clear approach to identify potential issues and implement precise solutions. The complexity of modern dual-power systems means careful attention is essential to maintain both reliability and optimal performance.

Below is a step-by-step guide to help address common diagnostic processes and troubleshooting steps in these sophisticated systems:

- System Check Procedures: Begin by running a thorough system scan. Utilizing specialized diagnostic tools helps reveal fault codes, enabling accurate analysis of each component’s status and identifying areas requiring further inspection.

- Battery Assessment: Power storage is critical. Evaluate the energy cells for consistency, voltage levels, and health status. Address any irregularities to prevent imbalances that can impact overall performance.

- Inverter Testing: The inverter converts power between different system components. Verify its efficiency through testing cycles to ensure smooth transitions and energy management.

- Cooling Systems: Efficient temperature regulation is essential for these power units. Inspect the cooling mechanism for fluid levels, leaks, or blockages, as overheating can lead to serious component degradation.

For persistent or complex issues, consult advanced troubleshooting guides or seek expert assistance. These measures ensure the system remains functional and extends the service life of essential components.

Brake System Service Tips

Maintaining the brake system is crucial for ensuring safe and reliable vehicle operation. A well-serviced brake system provides consistent stopping power, enhances control, and prevents wear-related issues that can compromise safety. Here are essential tips for handling brake maintenance effectively.

Inspect Brake Pads and Rotors Regularly: Checking the condition of brake pads and rotors is essential for preventing premature wear. Look for uneven pad thickness or scoring on the rotor surface, as these indicate the need for replacement or resurfacing.

Monitor Brake Fluid Levels: Brake fluid plays a pivotal role in the system’s responsiveness. Routinely check the fluid reservoir, ensuring the fluid is at the recommended level and has a clear color. Dark or murky fluid may need to be flushed and replaced to avoid reduced braking efficiency.

Examine Brake Lines and Hoses: Visual inspection of brake lines and hoses helps identify potential leaks or wear spots that may lead to fluid loss. Ensure that all connections are tight and hoses are free from cracks or bulges.

Proper lubrication of moving components, such as calipers, prevents friction and ensures smoother operation. Utilize high-temperature grease suitable for brake systems to reduce wear and prolong part life.

By following these maintenance practices, you enhance the performance and reliability of the braking system, contributing to a safer driving experience.

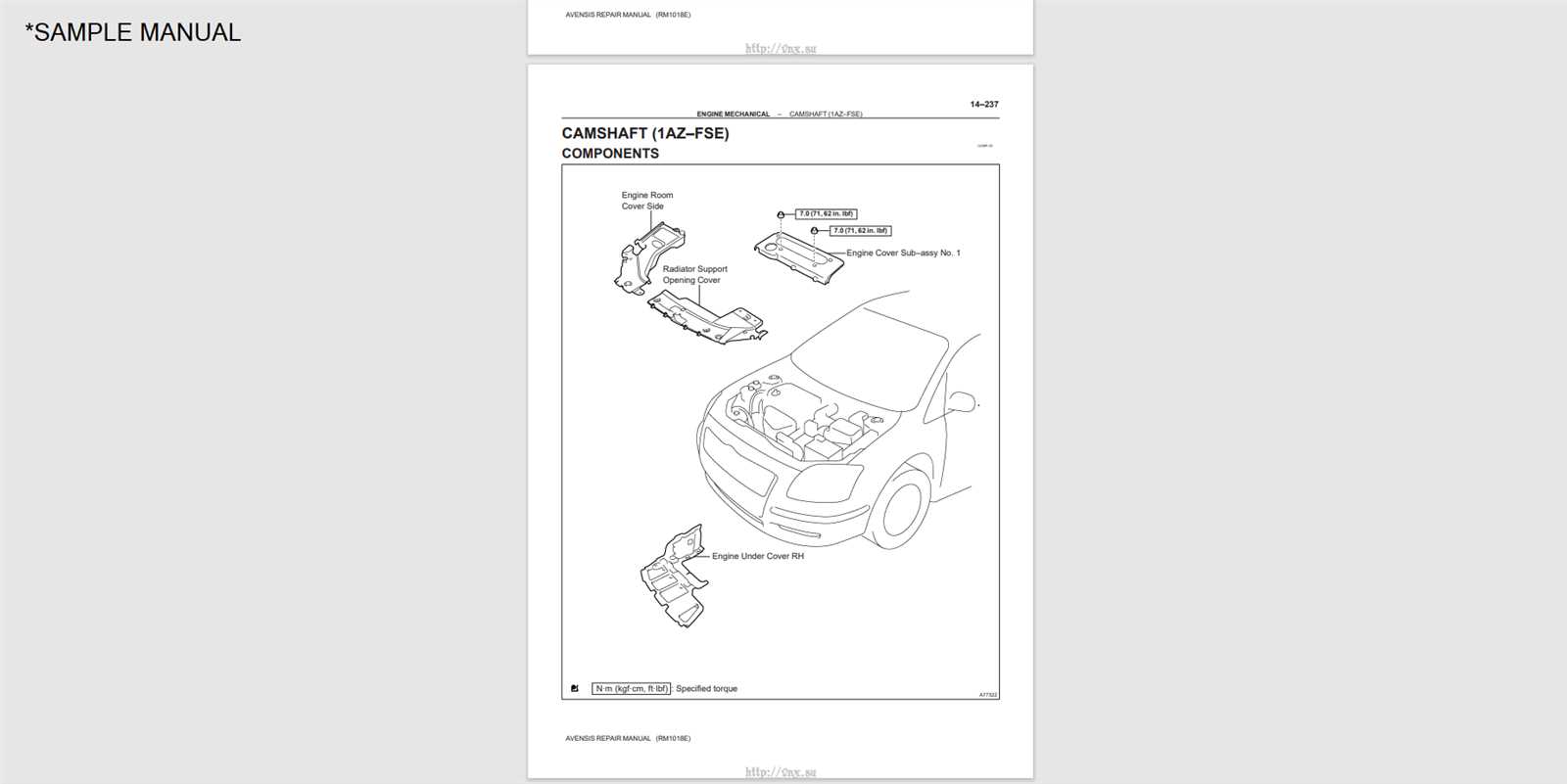

Engine Performance Optimization

Enhancing the efficiency and effectiveness of an engine is crucial for achieving optimal vehicle performance. This section discusses various strategies and modifications that can be implemented to maximize power output while maintaining fuel efficiency. By focusing on key areas such as air intake, exhaust flow, and engine management, significant improvements can be realized.

Key Areas for Improvement

Several components contribute to overall engine performance. Addressing these areas can lead to noticeable enhancements:

| Component | Optimization Strategy | Potential Benefits |

|---|---|---|

| Air Intake System | Upgrade to a high-flow air filter | Increased airflow, better throttle response |

| Exhaust System | Install a performance exhaust | Improved exhaust flow, enhanced sound |

| ECU Tuning | Reprogram the engine control unit | Optimized fuel maps, increased horsepower |

Maintenance Considerations

Regular maintenance plays a vital role in sustaining engine performance. Periodic checks and replacements of vital components ensure that the engine operates efficiently. Maintaining clean fuel injectors, timely oil changes, and ensuring proper spark plug function can prevent performance degradation over time.

Transmission Fluid Change Procedures

Changing the fluid in the transmission is a vital maintenance task that ensures optimal performance and longevity of the vehicle’s drivetrain. This procedure helps in maintaining the fluid’s integrity and protects the internal components from wear and tear. Regularly scheduled fluid changes can prevent overheating and enhance shifting smoothness.

Here are the essential steps for performing a transmission fluid change:

- Gather Required Tools and Materials:

- New transmission fluid (consult specifications for type and amount)

- Transmission filter (if applicable)

- Wrench set

- Fluid pump or funnel

- Drain pan

- Safety equipment (gloves, goggles)

- Prepare the Vehicle:

- Park the vehicle on a level surface and engage the parking brake.

- Allow the engine to cool down to avoid burns from hot fluids.

- Drain the Old Fluid:

- Locate the transmission drain plug and position the drain pan underneath it.

- Remove the drain plug and allow the old fluid to completely drain.

- Replace the Filter (if necessary):

- Remove the transmission pan (if applicable) to access the filter.

- Replace the old filter with a new one, ensuring a snug fit.

- Refill with New Fluid:

- Replace the drain plug securely.

- Using a funnel or fluid pump, refill the transmission with the appropriate new fluid.

- Check the fluid level with the dipstick (if applicable) and add more fluid if needed.

- Check for Leaks:

- Start the engine and let it run for a few minutes.

- Shift through all gear positions to circulate the fluid.

- Inspect for any leaks under the vehicle.

Regular fluid changes are crucial for maintaining a smooth and efficient transmission system. Following these procedures ensures that the vehicle remains reliable and performs at its best.

Electrical System Repairs and Inspections

The electrical system is crucial for the optimal functioning of a vehicle, ensuring all components operate efficiently. Regular checks and maintenance are essential to identify potential issues before they escalate. This section focuses on techniques and best practices for examining and servicing the electrical components, emphasizing the importance of safety and precision during the process.

During inspections, it is vital to pay attention to various elements within the electrical framework. Here is a summary of key components to examine:

| Component | Inspection Method | Common Issues |

|---|---|---|

| Batteries | Check for corrosion and ensure proper voltage levels. | Corrosion, low charge. |

| Wiring Harness | Inspect for fraying, damage, or loose connections. | Short circuits, disconnections. |

| Fuses | Verify the integrity of fuses and replace as necessary. | Burnt fuses, circuit overloads. |

| Alternator | Test output voltage and listen for unusual noises. | Insufficient power generation, wear. |

| Lighting Systems | Check functionality of headlights, taillights, and indicators. | Burnt bulbs, faulty switches. |

By adhering to these guidelines, vehicle owners can maintain the integrity of their electrical systems, prolonging the lifespan of components and enhancing overall performance. Regular inspections help in early detection of faults, ensuring a safe and reliable driving experience.

Cooling System Upkeep and Fixes

The maintenance and repair of the cooling system are essential for ensuring optimal engine performance and longevity. Regular attention to this system can prevent overheating and maintain proper operating temperatures, ultimately contributing to the overall health of the vehicle.

Key components of the cooling system include the radiator, water pump, thermostat, and hoses. Understanding the role of each element can help identify potential issues early and ensure timely interventions. Here are some maintenance tips:

- Regular Fluid Checks: Monitor coolant levels consistently, topping off as necessary with the appropriate type of coolant.

- Inspect Hoses and Clamps: Examine all hoses for signs of wear, leaks, or bulging. Replace any damaged hoses to prevent coolant loss.

- Radiator Maintenance: Keep the radiator clean and free of debris. Flushing the radiator periodically can remove buildup and improve efficiency.

- Thermostat Functionality: Test the thermostat regularly to ensure it opens and closes correctly. A malfunctioning thermostat can lead to temperature fluctuations.

- Water Pump Health: Listen for unusual noises that may indicate a failing water pump, and check for leaks around the pump area.

If overheating occurs or any component malfunctions, prompt diagnosis is critical. Some common issues may include:

- Coolant Leaks: Identify the source of leaks, whether from hoses, the radiator, or the water pump.

- Overheating: Investigate possible causes, such as low coolant levels, a faulty thermostat, or a clogged radiator.

- Cooling Fan Problems: Ensure that the cooling fan operates correctly; malfunctioning fans can lead to overheating.

By following these maintenance guidelines and addressing issues promptly, you can enhance the reliability and efficiency of the cooling system, ensuring a smoother and safer driving experience.

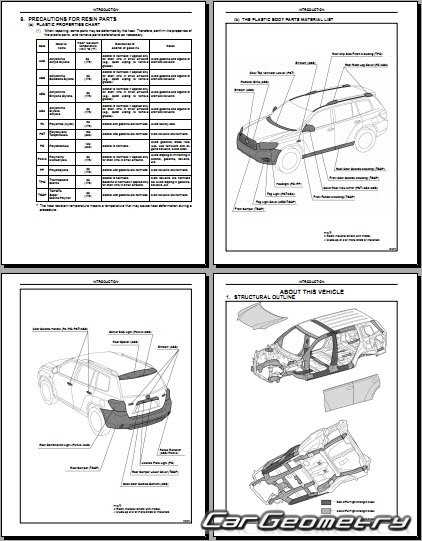

Interior and Exterior Care Techniques

Maintaining the aesthetic and functional aspects of a vehicle is essential for enhancing its lifespan and preserving its value. Regular attention to both the interior and exterior surfaces not only ensures a pleasant driving experience but also contributes to the overall performance of the automobile. This section provides essential techniques for effective upkeep, promoting longevity and visual appeal.

Exterior Maintenance Strategies

To protect the outer surface from environmental factors, it is crucial to implement a consistent cleaning routine. Start by rinsing the exterior with water to remove loose dirt and debris. Follow this with a gentle wash using a pH-balanced car shampoo, ensuring all areas, including crevices and wheel wells, are thoroughly cleaned. After washing, drying with a soft microfiber towel helps prevent water spots.

Interior Upkeep Practices

For the interior, begin by removing any trash and clutter to create a tidy environment. Utilize a vacuum to eliminate dust and debris from carpets, seats, and hard-to-reach areas. Apply appropriate cleaning solutions to surfaces such as dashboards and upholstery, ensuring to use products that are compatible with the materials. Regular conditioning of leather seats enhances their durability and prevents cracking, while periodic cleaning of windows ensures clear visibility.

By adopting these care techniques, you can significantly improve the condition of both the interior and exterior, ensuring a more enjoyable driving experience and extending the life of the vehicle.

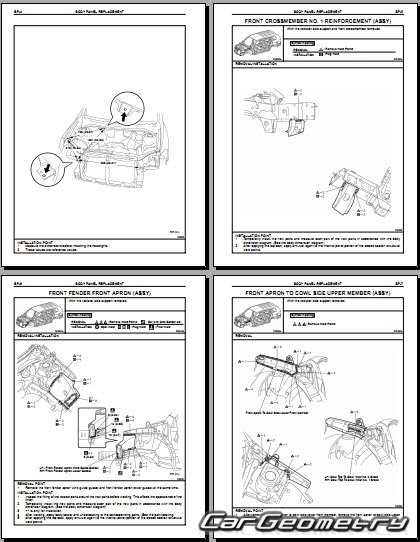

Suspension and Steering Adjustments

The proper alignment and calibration of the suspension and steering systems are essential for optimal vehicle performance and safety. Ensuring that these components function effectively contributes to improved handling, stability, and overall ride quality. This section outlines the key aspects to consider when making adjustments to these critical systems.

Suspension Settings

To achieve the desired comfort and control, suspension settings must be carefully evaluated. Adjusting the ride height, camber, and toe angles can significantly affect how the vehicle responds to various driving conditions. Maintaining the correct specifications helps prevent uneven tire wear and enhances traction.

Steering Calibration

Accurate steering calibration is vital for responsive handling. Regular checks of the steering linkage and the power steering system can help identify potential issues. Making necessary adjustments can improve the steering feel and ensure that the vehicle tracks straight, enhancing driver confidence on the road.

Understanding Warning Lights and Codes

Modern vehicles are equipped with intricate monitoring systems designed to ensure optimal performance and safety. These systems utilize various warning indicators and diagnostic codes to communicate potential issues to the driver. Recognizing and interpreting these signals is crucial for maintaining vehicle functionality and addressing problems promptly.

Common Warning Indicators

Warning lights on the dashboard serve as the first line of communication regarding the state of the vehicle. Each light is associated with a specific function, ranging from engine performance to safety features. For example, a check engine light may indicate a range of issues, from minor to severe, necessitating immediate attention. Other lights may pertain to the braking system, oil pressure, or battery status, each requiring appropriate action.

Diagnostic Trouble Codes (DTCs)

In addition to visual alerts, vehicles generate diagnostic trouble codes that provide deeper insights into underlying problems. These codes can be retrieved using specialized diagnostic tools and are essential for pinpointing issues accurately. Understanding these codes can aid technicians in efficiently diagnosing faults and ensuring the necessary repairs are conducted. Proper interpretation of both warning lights and codes is vital for prolonging the life of the vehicle and enhancing overall safety.

Fuel System Cleaning and Repairs

Maintaining the efficiency of a vehicle’s fuel delivery system is crucial for optimal performance and longevity. Over time, contaminants and deposits can accumulate, leading to reduced fuel flow and combustion efficiency. Regular cleaning and timely interventions can prevent costly repairs and ensure the engine operates smoothly.

Cleaning Procedures

To restore the fuel system’s functionality, various cleaning methods can be employed. One effective approach is the use of specialized fuel additives designed to break down and eliminate carbon buildup and other impurities. These additives can be introduced directly into the fuel tank, allowing them to mix with the fuel and circulate through the system. Additionally, using a fuel injector cleaning kit can provide a more thorough cleanse by targeting injectors directly, removing deposits that hinder their performance.

Common Repairs

In some cases, mechanical issues may necessitate repairs beyond cleaning. Faulty fuel pumps, clogged filters, or damaged injectors may require replacement to restore proper functionality. It is essential to diagnose these problems early to avoid further complications. Regular inspections can help identify signs of wear or damage, allowing for timely maintenance and extending the lifespan of the fuel delivery system.