Comprehensive Guide to Hotsy Pressure Washer Repair

When it comes to maintaining your high-efficiency cleaning equipment, understanding the intricacies of its components and functions is essential. This section provides a comprehensive overview, ensuring that users can address common challenges effectively. With the right knowledge, you can prolong the lifespan of your device and optimize its performance.

The focus here is on practical strategies and troubleshooting techniques that empower users to tackle issues independently. By following systematic approaches, users can identify problems early and implement solutions without the need for professional assistance. This guide serves as a valuable resource, offering insights into the various aspects of upkeep and common repairs.

In the following sections, detailed instructions and helpful tips will equip users with the confidence to handle maintenance tasks efficiently. Emphasizing the importance of regular checks and proper care, this guide encourages proactive measures that will enhance the reliability and effectiveness of your equipment.

Understanding Hotsy Pressure Washers

This section aims to provide insight into high-performance cleaning machines designed for efficient and effective surface cleaning. These devices utilize powerful jets of water to remove dirt, grime, and stains from various surfaces, making them essential tools for both commercial and residential use.

Typically, these cleaning units are characterized by their robust construction and the ability to handle tough cleaning tasks. Users can find a variety of models equipped with different features to cater to specific cleaning needs. Understanding the components and functionalities of these machines can significantly enhance their operation and maintenance.

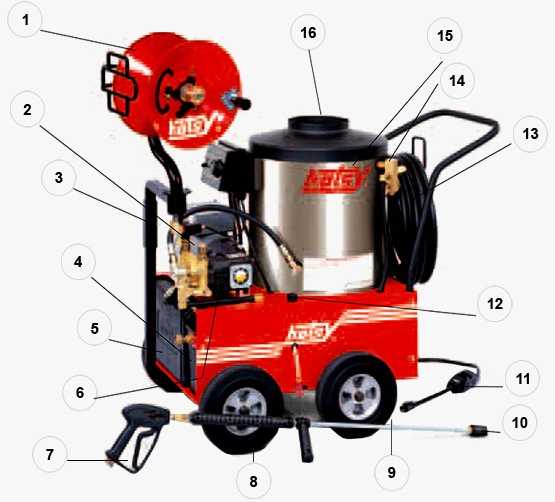

Key Components: Each machine consists of essential parts such as a motor, pump, and nozzle, which work together to generate the required pressure and flow. Knowing how these elements interact can aid in troubleshooting and maximizing performance.

Maintenance Tips: Regular upkeep is vital for longevity. Users should familiarize themselves with proper cleaning, storage, and servicing practices to ensure optimal functionality. Attention to detail during maintenance can prevent common issues and enhance overall efficiency.

Common Issues with Hotsy Models

This section addresses frequent problems encountered with certain cleaning equipment, focusing on various symptoms and solutions. Understanding these challenges can help users maintain optimal performance and prolong the lifespan of their devices.

- Insufficient Water Flow: This issue often arises from clogged filters or hoses.

- Inconsistent Temperature: Fluctuating temperatures may indicate a malfunctioning thermostat.

- Strange Noises: Unusual sounds can result from loose components or worn-out parts.

- Pressure Loss: A drop in pressure could be linked to a faulty pump or air leaks in the system.

- Frequent Shutdowns: This may happen due to overheating, often caused by blocked vents.

Addressing these common issues promptly can ensure the equipment operates efficiently and effectively.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing issues in any machine. This section outlines the fundamental instruments that will aid in the maintenance and troubleshooting of your unit, ensuring optimal performance.

- Wrenches: A variety of sizes will help you loosen or tighten bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are necessary for various fastening tasks.

- Pliers: These are useful for gripping, twisting, and cutting wires or components.

- Socket Set: A comprehensive set allows for quick and efficient fastening and loosening of bolts.

- Multimeter: Essential for checking electrical connections and diagnosing issues.

In addition to these basic tools, consider having the following items on hand for more specialized tasks:

- Cleaning Solutions: Effective for maintaining components and ensuring proper function.

- Replacement Parts: Having common spare components can save time during repairs.

- Protective Gear: Gloves and goggles will help ensure safety while working on machinery.

Equipping yourself with these essential tools will facilitate smoother maintenance processes and extend the lifespan of your unit.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues associated with cleaning machines. By following a systematic method, users can identify problems and implement effective solutions to restore functionality.

Start by ensuring that the equipment is properly connected to the power source and that all switches are in the correct positions. Check for any visible signs of damage or wear on hoses and connections, as these can often lead to performance issues.

If the machine fails to operate, verify that the power supply is active. Use a multimeter to test the electrical components for continuity and ensure that fuses or circuit breakers have not tripped.

Next, examine the fluid flow. Ensure that there are no clogs in the inlet filter or the hoses. If fluid is not flowing correctly, detach the hoses and inspect them for blockages or kinks that could restrict flow.

After confirming that the supply line is clear, check the nozzle and any attachments for obstructions. Cleaning or replacing these components can significantly improve performance.

Finally, consult the troubleshooting charts often included in the product documentation for specific error codes or symptoms. This resource can provide valuable insights and pinpoint solutions tailored to the identified issues.

Replacing Hotsy Pump Components

When it comes to maintaining the efficiency of your cleaning equipment, addressing component failures is essential. Over time, certain parts may wear out, leading to decreased performance. This section provides guidance on the steps to take when replacing these key elements, ensuring that your machinery operates at its best.

Start by identifying the components that require replacement. Common parts include seals, valves, and pistons. Once you’ve pinpointed the faulty items, gather the necessary tools and replacement components to facilitate the process.

Before proceeding, ensure the equipment is disconnected from any power source. Carefully disassemble the pump, taking note of how each part fits together. This will aid in the reassembly process later. Replace the worn components with new ones, making sure they are compatible with your equipment.

After replacing the parts, reassemble the unit following the reverse order of disassembly. Ensure all connections are secure and that there are no loose parts. Finally, test the equipment to confirm that it functions correctly and efficiently, free from leaks or operational issues.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cleaning equipment involves regular upkeep and attention to detail. Implementing simple yet effective practices can significantly enhance performance and extend the lifespan of your device.

- Regular Inspection: Check for any signs of wear or damage. Early detection can prevent more serious issues.

- Cleaning After Use: Rinse off any debris or buildup after each use. This helps maintain optimal functionality.

- Fluid Levels: Regularly monitor and replace fluids as necessary to ensure proper operation.

- Storage Conditions: Keep the equipment in a dry and sheltered environment to protect it from the elements.

- Scheduled Maintenance: Follow a maintenance schedule that includes professional servicing at regular intervals.

By adhering to these straightforward guidelines, you can keep your cleaning equipment in excellent condition, ensuring it serves you well for many years to come.

Identifying Electrical Problems

Diagnosing issues related to electrical components is crucial for maintaining optimal performance of any device. Understanding potential malfunctions can help in pinpointing the root cause and facilitating effective solutions.

Common Symptoms

Recognizing the signs of electrical failure is the first step in troubleshooting. Below are some typical indicators that may suggest underlying issues:

| Symptom | Description |

|---|---|

| Device Not Starting | Failure to power on can indicate problems with the power source or internal circuitry. |

| Unusual Noises | Strange sounds during operation may suggest loose connections or component wear. |

| Overheating | Excessive heat can point to electrical overloads or insufficient ventilation. |

| Fluctuating Power | Inconsistent performance may be due to faulty connections or unstable voltage supply. |

Initial Diagnostic Steps

Once symptoms are identified, the next step is to conduct basic tests to confirm the nature of the problem. Here are some initial approaches:

- Check all power connections to ensure they are secure and free from corrosion.

- Use a multimeter to measure voltage levels at various points in the system.

- Inspect circuit boards for visible damage, such as burnt components or broken traces.

How to Clean Spray Nozzles

Maintaining optimal performance of your cleaning equipment often involves ensuring that the spraying components are clear and functional. Clogged or dirty nozzles can diminish the effectiveness of your machine, leading to unsatisfactory results. This section will guide you through simple steps to restore your nozzles to their best condition.

Gather Necessary Supplies

Before starting the cleaning process, collect the required tools and materials. You will need:

- A soft brush or toothbrush

- Warm water

- Liquid detergent

- A small container for soaking

- A safety pin or needle

Cleaning Process

Begin by removing the nozzles from the main unit. Soak them in a mixture of warm water and detergent for about 15 minutes to loosen any debris. After soaking, use the brush to gently scrub the nozzles, paying attention to any build-up. For stubborn blockages, carefully insert the safety pin or needle into the nozzle openings to dislodge dirt. Rinse thoroughly with clean water to remove any remaining soap and debris.

Finally, allow the nozzles to dry completely before reattaching them to the machine. Regular cleaning will help maintain performance and prolong the lifespan of your equipment.

Winterizing Your Pressure Washer

Preparing your equipment for the cold months is essential to ensure its longevity and optimal performance. Properly safeguarding your unit against freezing temperatures can prevent damage and costly repairs. This process involves a few key steps that will help maintain the functionality of your equipment during the off-season.

Step 1: Drain All Water

Begin by disconnecting the water supply and removing any hoses. It is crucial to drain all residual water from the system to avoid freezing and cracking. Turn on the unit briefly to expel any remaining liquid from the internal components.

Step 2: Use Antifreeze Solution

After draining, consider running a non-toxic antifreeze solution through the system. This will provide additional protection against freezing temperatures. Follow the manufacturer’s recommendations for the type and quantity of antifreeze to use.

Step 3: Store in a Controlled Environment

Finally, store your equipment in a dry, sheltered location where temperatures remain stable. Avoid leaving it outside, as exposure to harsh weather conditions can lead to significant damage. Make sure the area is free from moisture to further protect your investment.

By following these essential steps, you can ensure your equipment remains in excellent condition, ready for use when warmer weather returns.

Finding Replacement Parts Easily

Locating components for maintenance and enhancement can often seem daunting. However, with the right approach and resources, you can simplify the process and ensure your equipment remains in top condition. Below are some effective strategies to streamline your search for necessary items.

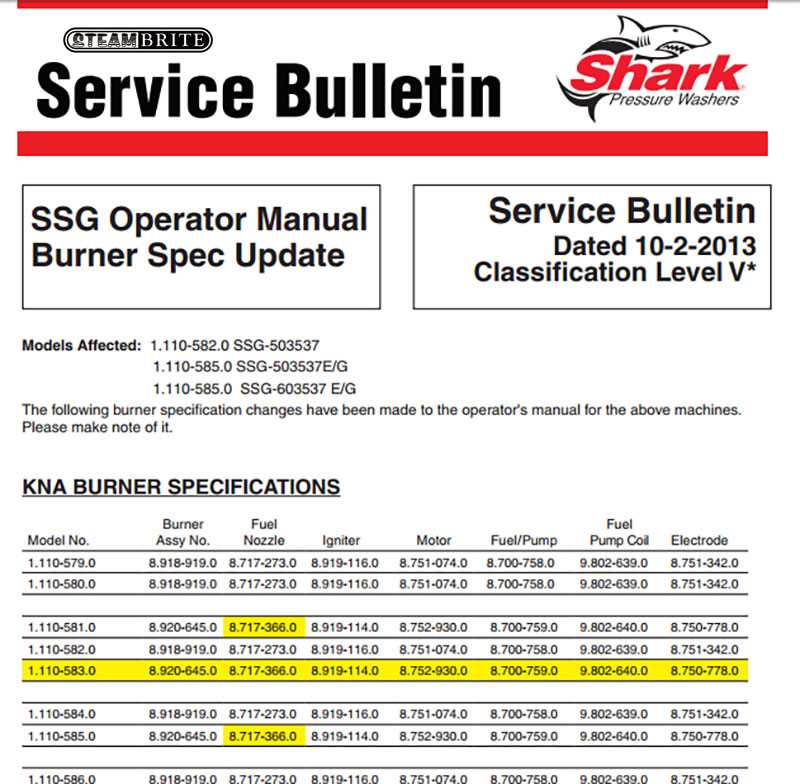

Start by identifying the specific components you need. Reference your original documentation or use manufacturer resources to obtain part numbers. This will help narrow down your search significantly.

Utilize various platforms to find the required items:

| Source | Description |

|---|---|

| Online Retailers | Websites that specialize in equipment parts often have extensive inventories and user-friendly search options. |

| Local Dealers | Contacting authorized distributors can provide access to genuine parts and expert advice. |

| Online Marketplaces | Platforms like eBay or Amazon may offer a variety of new and used components at competitive prices. |

| Community Forums | Engaging in online forums or social media groups can connect you with other users who may have recommendations or spare parts. |

By leveraging these resources, you can effectively locate the necessary components for your maintenance tasks, ensuring smooth operation and longevity of your equipment.