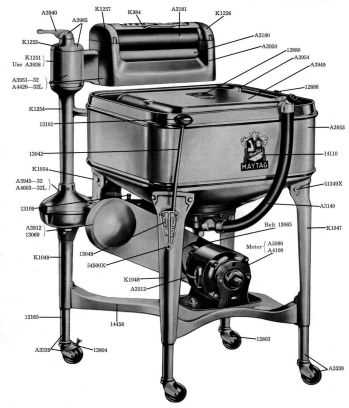

Comprehensive Guide to Maytag Clothes Washer Repair

Maintaining and ensuring the efficiency of household equipment is essential for smooth daily operations. This section provides valuable insights into the common issues faced by users and effective strategies for addressing them. With the right knowledge and tools, users can navigate the complexities of these appliances and enhance their performance.

Understanding the various components and their functions is crucial for identifying problems that may arise. This guide delves into typical malfunctions and offers practical solutions to restore optimal functionality. From diagnosing issues to implementing fixes, users will find comprehensive information tailored to assist them in their troubleshooting endeavors.

Whether it’s a minor hiccup or a more significant challenge, having access to a structured resource can make all the difference. With clear instructions and expert advice, users can confidently tackle any situation and ensure their laundry equipment operates smoothly for years to come.

Common Issues with Maytag Washers

Home appliances often encounter various challenges that can disrupt their functionality. Understanding these frequent problems can help users troubleshoot effectively and maintain their devices in optimal condition.

Inconsistent Operation

A common issue involves the unit failing to operate consistently. This can manifest as unexpected stops or difficulties in starting cycles. Often, these problems stem from electrical connections, door latches, or control settings that require adjustment or inspection.

Water Drainage Problems

Another prevalent concern is ineffective drainage. Users may notice that water remains in the tub after a cycle. This can result from clogged hoses, malfunctioning pumps, or blocked filters. Regular maintenance and cleaning of these components can significantly enhance performance.

Troubleshooting Noisy Operation

Unusual sounds during the operation of a fabric-cleaning appliance can indicate underlying issues that require attention. Identifying the source of these noises is essential for restoring optimal performance and ensuring longevity. This section provides guidance on diagnosing and resolving common auditory disturbances.

Common Causes of Noise

Several factors can contribute to excessive noise during the functioning of the appliance. Understanding these causes can help in effective troubleshooting:

| Noise Type | Possible Cause | Recommended Action |

|---|---|---|

| Thumping | Unbalanced load | Redistribute items evenly |

| Rattling | Loose foreign objects | Check drum for items like coins |

| Squeaking | Worn drum bearings | Inspect and replace if necessary |

| Grinding | Faulty motor coupling | Examine coupling and replace if damaged |

Steps for Resolution

To effectively address the identified issues, follow these steps:

- Disconnect the appliance from power for safety.

- Examine the drum for any trapped items or blockages.

- Check for uneven loads and adjust as needed.

- Inspect moving parts for wear and replace any that are damaged.

Water Leakage Solutions

Addressing issues related to moisture escape is crucial for maintaining the functionality and longevity of your appliance. Understanding the common causes of leaks can help in effectively mitigating the problem and preventing future occurrences.

First, inspect the hoses for any signs of wear or damage. Cracks or loose connections can lead to significant fluid loss. Replacing old or frayed hoses is often a simple yet effective solution.

Next, check the door seals or gaskets. Over time, these components can become worn or dirty, leading to improper closures. Regular cleaning and timely replacements can help ensure a tight seal.

Additionally, evaluate the drainage system. Blockages or clogs can cause backflow, resulting in leaks. Keeping the drainage path clear is essential for proper function.

Lastly, consider the levelness of the unit. If the appliance is not balanced, it may result in uneven water distribution and leaks. Adjusting the feet of the machine can resolve this issue, providing stability and preventing unnecessary movement during operation.

Understanding Control Panel Functions

The control panel serves as the central hub for managing operations and settings of your appliance. Familiarizing yourself with its features can enhance efficiency and improve user experience. This section delves into the various components that enable effective functionality.

Main Controls

The primary controls typically include buttons and dials that allow you to select different modes and customize cycles. Understanding each option ensures you make informed choices for optimal results. Look for indicators that provide feedback on the current status of the appliance.

Additional settings may include temperature adjustments, spin speed variations, and specific cycle selections tailored for different fabrics. Utilizing these features not only promotes better performance but also contributes to the longevity of your items. Pay attention to user manuals for detailed descriptions of each setting.

Maintaining Optimal Spin Cycles

Ensuring efficient spin cycles is crucial for achieving maximum drying effectiveness and prolonging the lifespan of your laundry appliance. Proper maintenance and understanding of how various factors influence performance can lead to improved results, saving both time and energy. Regular checks and adjustments can help prevent common issues that may disrupt the spinning process.

Regular Maintenance Checks

Routine inspections play a significant role in maintaining spinning efficiency. Ensure that the drum is free of foreign objects and that the door seal is clean and intact. Regularly check the drive belt for any signs of wear, as a damaged belt can significantly hinder performance. Additionally, verify that the appliance is level; an uneven setup can cause vibrations and affect the effectiveness of spin cycles.

Optimizing Load Management

Understanding load distribution is key to achieving optimal performance. Avoid overloading the drum, as this can lead to inadequate spinning and wet laundry at the end of the cycle. Instead, load items evenly to promote balanced spinning. Separating heavier items from lighter ones can also enhance efficiency, ensuring that the mechanism operates smoothly and effectively throughout the cycle.

How to Replace a Door Seal

Replacing a door gasket is a crucial maintenance task that ensures proper sealing and efficiency of the appliance. A worn or damaged seal can lead to leaks and inadequate performance, making it essential to address this issue promptly. This guide outlines the steps needed to successfully install a new gasket, ensuring a tight fit and optimal functionality.

Follow these steps for a smooth replacement process:

| Step | Description |

|---|---|

| 1 | Unplug the appliance to ensure safety while working. |

| 2 | Remove the front panel by unscrewing any screws holding it in place. |

| 3 | Carefully detach the old gasket from the door frame, noting its placement for reference. |

| 4 | Clean the surface area thoroughly to remove any residue or debris. |

| 5 | Align the new seal with the door frame, ensuring it fits snugly into place. |

| 6 | Reattach the front panel and secure it with screws. |

| 7 | Plug the appliance back in and run a test cycle to check for leaks. |

By following these steps, you can effectively replace the door seal, enhancing the overall performance and longevity of the appliance.

Fixing Drainage Problems

Addressing issues related to water removal is essential for maintaining the functionality of your appliance. Often, improper drainage can lead to a host of complications, including inefficient operation and potential damage. Identifying the root cause is the first step toward a solution.

Common Causes

Several factors may contribute to drainage failures. Blocked hoses or filters are frequent culprits, as they prevent water from flowing freely. Additionally, issues with the pump, such as clogs or mechanical failures, can impede proper operation.

Steps to Diagnose

Begin by inspecting the drain hose for kinks or blockages. Ensure it is correctly positioned and not submerged in water. Next, examine the filter, if accessible, to remove any debris. If these components are clear, test the pump for functionality by listening for unusual sounds during operation.

Resolving Issues

If a blockage is found, clear it carefully to restore normal function. In cases where the pump appears faulty, replacement may be necessary. Consulting the specific guidelines for your unit will provide additional instructions on parts and assembly.

Taking these steps can help restore proper water drainage, ensuring your appliance runs smoothly and efficiently.

Diagnosing Electrical Failures

Identifying issues related to electrical systems is crucial for effective troubleshooting. Various components can lead to malfunctions, and understanding the signs of these problems can save time and resources. This section provides guidance on recognizing and resolving common electrical challenges.

Begin with Basic Checks: Start by ensuring that the power supply is functioning correctly. Check for blown fuses or tripped circuit breakers, as these are frequent culprits behind operational failures. A simple reset may restore functionality.

Inspect Wiring Connections: Examine all electrical connections for signs of wear, corrosion, or looseness. Damaged wires can interrupt power flow, leading to erratic behavior or complete shutdowns. Tightening connections or replacing faulty wires can often resolve these issues.

Utilize Diagnostic Tools: Employ multimeters or continuity testers to measure voltage and check for continuity in circuits. These tools can help identify faulty components, such as switches or relays, which may need replacement.

Review User Indicators: Pay attention to any error codes or warning lights. Referencing the relevant documentation can provide insights into specific failures and guide troubleshooting efforts effectively.

By systematically following these steps, identifying and addressing electrical failures can become a more manageable task, ultimately enhancing the performance and longevity of the appliance.

Dealing with Agitator Issues

When it comes to addressing problems related to the spinning mechanism of your laundry appliance, understanding the common issues can significantly enhance performance. This section will guide you through recognizing symptoms and taking steps to rectify them effectively.

Common Symptoms

Several indicators can suggest that the agitation component is not functioning properly. Below is a table outlining these symptoms and their potential causes:

| Symptom | Possible Cause |

|---|---|

| No movement during cycle | Faulty drive belt or motor |

| Unusual noises | Loose or worn components |

| Inconsistent agitation | Worn gears or linkage issues |

| Jamming or sticking | Debris accumulation or damaged parts |

Troubleshooting Steps

To effectively troubleshoot these issues, begin by unplugging the device for safety. Inspect the agitation mechanism for any visible wear or damage. Cleaning out any debris can often resolve sticking problems. If the issue persists, testing the motor and associated components for electrical faults may be necessary.

Regular Maintenance Tips

Ensuring the longevity and optimal performance of your home appliance requires consistent upkeep. Implementing a few simple practices can prevent common issues and enhance efficiency over time. Regular checks and maintenance tasks are essential to keep everything running smoothly.

Essential Maintenance Tasks

Incorporating the following practices into your routine can significantly improve the functionality of your device:

| Task | Frequency | Description |

|---|---|---|

| Check Hoses | Monthly | Inspect hoses for signs of wear or leaks. Replace if necessary to prevent flooding. |

| Clean Filters | Every 3 Months | Remove and clean filters to ensure proper water flow and prevent blockages. |

| Inspect Seals | Biannually | Examine door seals for any cracks or mold. Replace if damaged to maintain efficiency. |

| Level the Appliance | As Needed | Check and adjust leveling feet to prevent excessive vibrations during operation. |

Additional Tips for Care

Beyond routine checks, consider the following advice to extend the lifespan of your appliance:

- Avoid overloading the appliance to ensure effective cleaning and prevent strain.

- Utilize the appropriate detergent and follow dosage guidelines to prevent residue build-up.

- Run an empty cycle with vinegar occasionally to eliminate odors and build-up.

Parts Replacement Guide

When addressing issues with your laundry appliance, understanding how to effectively replace components is crucial for restoring functionality. This section provides an overview of essential parts and the steps necessary for their successful substitution, ensuring your device operates smoothly once again.

Identifying Faulty Components

Before proceeding with any replacements, it is vital to accurately identify the malfunctioning parts. Common signs of wear may include unusual noises, leaks, or failure to complete cycles. Conducting a thorough inspection will help pinpoint the specific components that need attention, making the replacement process more efficient.

Steps for Successful Replacement

Once you have identified the faulty parts, follow these general steps for replacement:

- Gather Tools: Ensure you have the necessary tools such as screwdrivers, pliers, and replacement components.

- Power Off: Always disconnect the appliance from the power source to ensure safety during the process.

- Access the Component: Remove any panels or covers that obstruct access to the faulty part.

- Remove and Replace: Carefully detach the old component and install the new one, ensuring all connections are secure.

- Test Functionality: Once the replacement is complete, reconnect the power and run a test cycle to confirm that the issue has been resolved.

By following these guidelines, you can ensure a smoother experience when dealing with part replacements, ultimately enhancing the longevity and performance of your appliance.

Cleaning the Washer Interior

Maintaining the cleanliness of the inner compartments of your appliance is essential for optimal performance and longevity. Regularly addressing the buildup of detergent residue, lint, and other debris will not only enhance efficiency but also help prevent unpleasant odors.

Steps for Effective Cleaning

To start, gather a few basic supplies: a soft cloth, white vinegar, and baking soda. Begin by wiping down the interior surfaces with a damp cloth to remove any loose particles. For a deeper clean, mix equal parts of white vinegar and water, and use this solution to thoroughly scrub the drum and any visible parts. This natural cleaner helps dissolve stubborn deposits.

Additional Tips

For those tough spots, sprinkle some baking soda onto the damp areas and scrub gently. Allow the mixture to sit for a few minutes before wiping it away. To further eliminate odors, run a hot cycle with just vinegar or a specialized cleaner. Regular maintenance will keep your appliance fresh and functioning smoothly.

Safety Precautions for Repairs

When undertaking maintenance tasks on household appliances, it is essential to prioritize safety to prevent accidents and injuries. Understanding the risks associated with working on electrical and mechanical components is crucial for a successful and secure process.

Firstly, always disconnect the device from its power source before beginning any work. This step eliminates the risk of electrical shock and ensures a safer environment. Additionally, it is advisable to use tools that are in good condition and designed specifically for the job.

Wearing appropriate personal protective equipment is also vital. Gloves, safety goggles, and sturdy footwear can help protect against potential hazards. Furthermore, maintaining a clean workspace free of clutter reduces the chances of tripping or mishandling tools.

Lastly, familiarize yourself with the specific features of the appliance you are working on. Consulting relevant guides or documentation can provide valuable insights and enhance your understanding of the components involved, contributing to a safer and more effective maintenance experience.