Yamaha 115 Outboard Maintenance Guide

Ensuring the longevity and optimal performance of marine propulsion systems is crucial for any boating enthusiast. This section delves into the essential practices and techniques required to maintain these powerful machines effectively. A well-kept engine not only enhances the reliability of your vessel but also contributes to a more enjoyable experience on the water.

Within these guidelines, you will discover various methods for troubleshooting common issues, performing routine checks, and executing necessary adjustments. Understanding the intricacies of your engine will empower you to take proactive measures, preventing minor problems from escalating into major setbacks.

By familiarizing yourself with the recommended practices, you will gain confidence in handling maintenance tasks. This knowledge serves as a foundation for successful engine management, ensuring that your watercraft remains in peak condition throughout the seasons.

To ensure the longevity and efficiency of marine engines, having the right tools is crucial. This section highlights the fundamental equipment necessary for routine upkeep and troubleshooting, enabling users to perform maintenance tasks effectively.

Key Maintenance Tools

The following tools are essential for any maintenance routine, helping to facilitate repairs and adjustments:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For various screw types found on the engine. |

| Pliers | For gripping and bending wire or other materials. |

| Fuel Line Cutter | To safely cut fuel lines without damage. |

| Torque Wrench | Ensures proper tightening of bolts to manufacturer specifications. |

Safety Equipment

In addition to maintenance tools, safety equipment is vital for protecting oneself during repair work:

| Equipment | Function |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals. |

| Gloves | Provides grip and protects hands from sharp objects. |

| Life Jacket | Essential for safety when working near water. |

Understanding Engine Components

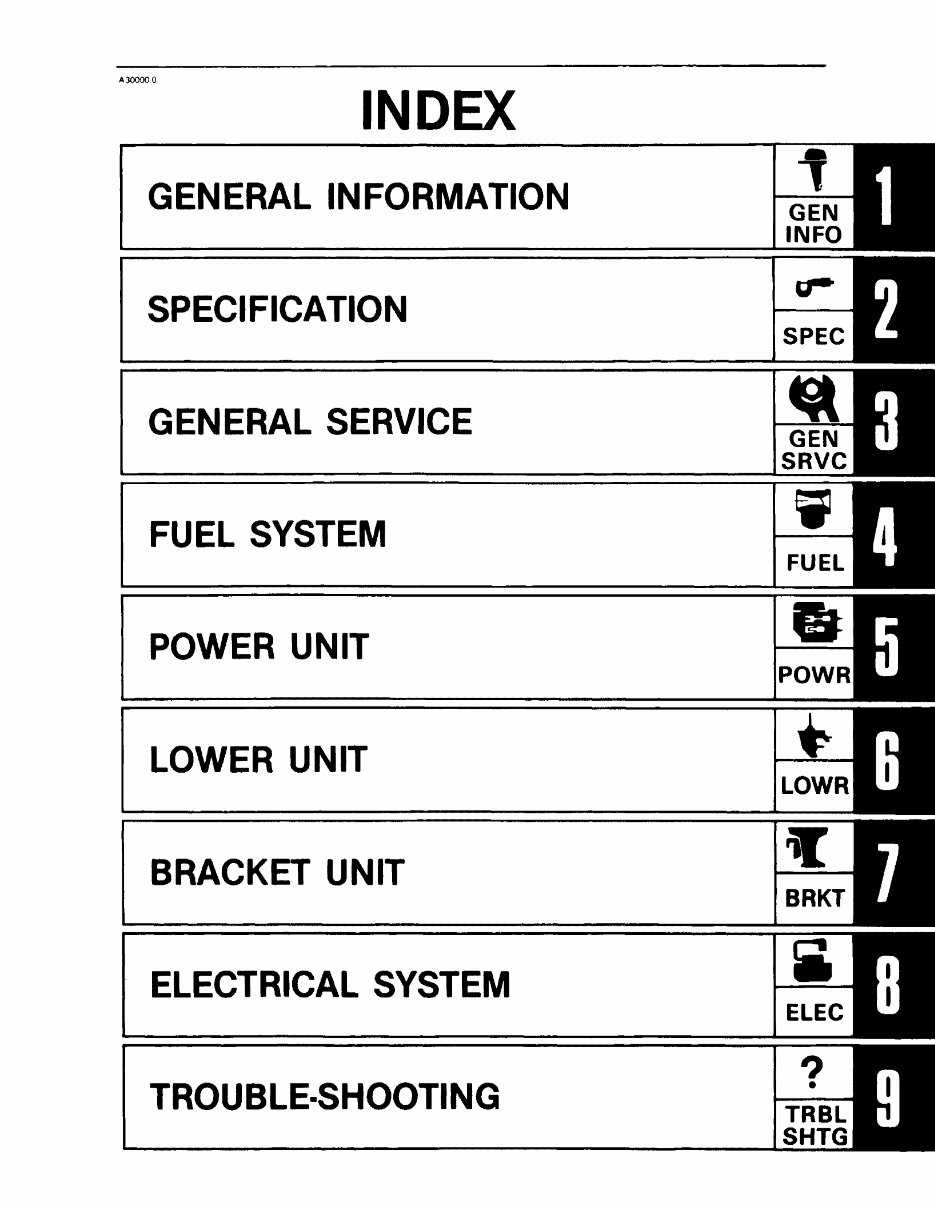

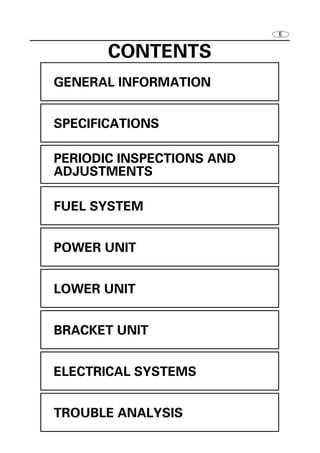

Grasping the various elements that constitute an engine is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall functionality, contributing to performance and reliability. Familiarity with these components allows for better diagnostics and enhanced operational efficiency.

Engines comprise several key sections, each designed to work in unison. Below is a table that outlines the primary components and their functions:

| Component | Function |

|---|---|

| Powerhead | Generates power through combustion. |

| Lower Unit | Houses the gear system and propeller. |

| Fuel System | Delivers fuel to the combustion chamber. |

| Cooling System | Regulates engine temperature to prevent overheating. |

| Ignition System | Creates the spark that ignites the fuel-air mixture. |

Understanding these components and their interactions can significantly enhance the ability to maintain and optimize engine performance.

Troubleshooting Common Issues

This section aims to guide users in identifying and resolving frequent problems that may arise during operation. Understanding the underlying causes of these issues can significantly enhance performance and longevity.

- Starting Difficulties:

- Check the fuel supply and ensure it is fresh and properly mixed.

- Inspect the battery for charge and connections.

- Examine the ignition system for faults.

- Overheating:

- Ensure that the cooling system is functioning and not obstructed.

- Check the water intake for blockages.

- Verify that the proper coolant levels are maintained.

- Unusual Noises:

- Investigate for any loose components or wear in moving parts.

- Listen for irregular sounds from the propeller or gear system.

- Assess for proper lubrication of all mechanical parts.

- Poor Performance:

- Evaluate the fuel quality and delivery system.

- Inspect the propeller for damage or improper size.

- Check the engine settings and calibrations.

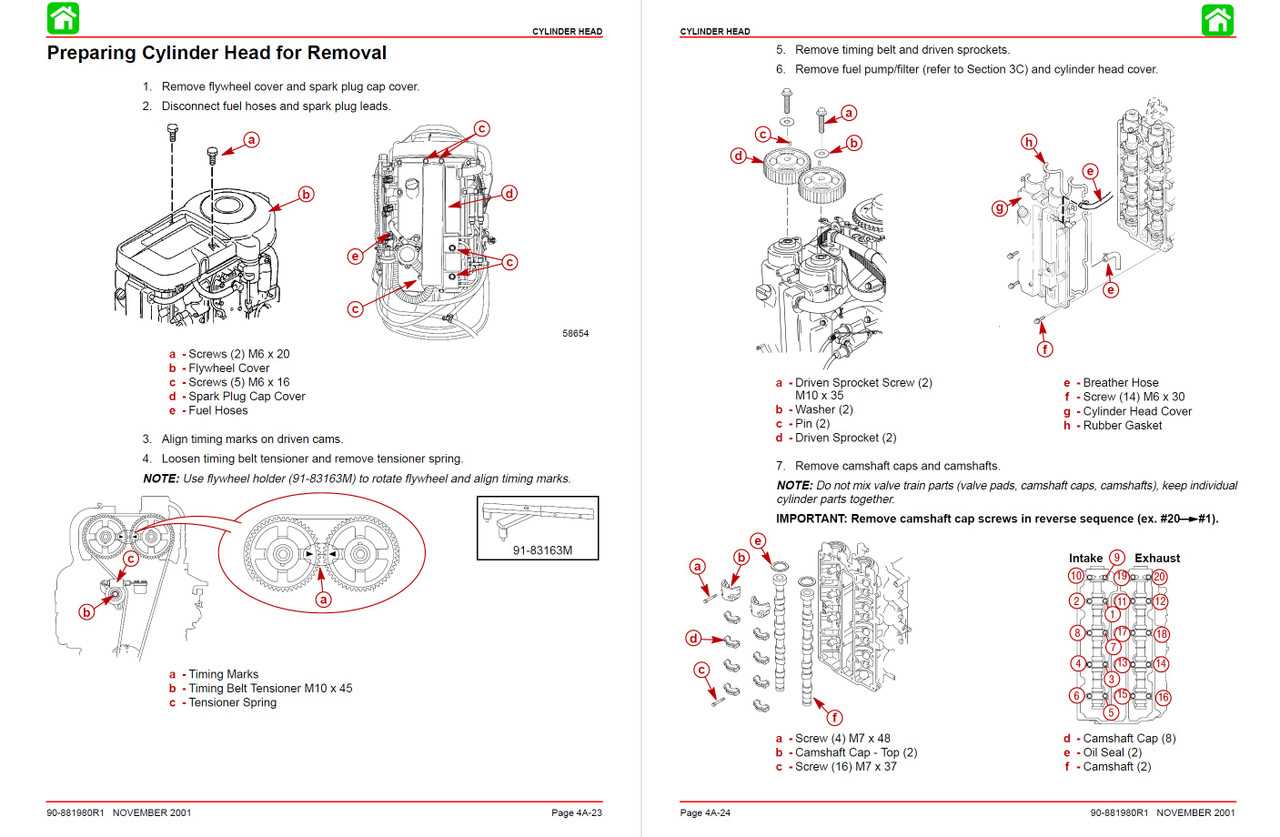

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with marine propulsion systems. Following a structured process ensures effective troubleshooting and restoration, enhancing the overall performance and longevity of your equipment.

Begin by gathering all necessary tools and materials before starting the procedure. A well-organized workspace will streamline your efforts and reduce the likelihood of missing crucial steps.

| Step | Description |

|---|---|

| 1 | Inspect the motor for visible signs of damage or wear. Check all components to ensure they are intact. |

| 2 | Disconnect the power source to prevent any accidental start-ups during the process. |

| 3 | Remove the cover to access internal parts. Carefully document any connections or configurations for reassembly. |

| 4 | Examine the fuel system for clogs or leaks. Clean or replace parts as necessary to maintain proper function. |

| 5 | Check the electrical system for faults. Test connections and replace any damaged wires or connectors. |

| 6 | Reassemble all components according to your documentation, ensuring all connections are secure. |

| 7 | Reconnect the power source and perform a test run to verify that the system operates smoothly. |

Following these steps meticulously will facilitate effective restoration and enhance the functionality of your marine propulsion unit.

Fuel System Adjustments

Proper tuning of the fuel system is essential for optimal performance and efficiency of marine engines. Adjustments can significantly influence the engine’s power output, fuel consumption, and overall reliability. This section will guide you through the key modifications needed for achieving the best results.

Initial Setup

Before making any changes, ensure that the engine is in good working order. Here are some preliminary steps:

- Check the fuel quality and replace if necessary.

- Inspect all hoses and connections for leaks.

- Ensure the fuel filter is clean and functioning.

Adjustment Techniques

Once the initial setup is complete, proceed with the following adjustments:

- Mixture Ratio: Adjust the air-fuel mixture to ensure efficient combustion. This may involve tweaking the carburetor settings.

- Idle Speed: Set the idle speed according to the specifications to maintain smooth operation.

- Linkage Alignment: Verify that the throttle and choke linkages are properly aligned for responsive control.

By following these guidelines, you can enhance the performance of the marine engine, ensuring it runs smoothly and efficiently. Regular checks and adjustments will contribute to longevity and reliability in various conditions.

Electrical System Inspection

The electrical system plays a crucial role in the overall functionality of any watercraft. Regular assessment of this system ensures optimal performance and safety during operation. It is essential to verify that all components are in good working condition and free from any potential issues.

Begin by examining the battery. Ensure it is securely mounted and the terminals are clean and free of corrosion. A weak or damaged battery can lead to inadequate power supply, affecting the performance of various electrical components.

Next, check the wiring. Inspect all cables for signs of wear, fraying, or damage. Ensure that connections are tight and free from moisture. Loose or damaged wiring can lead to shorts or complete electrical failures.

Additionally, test the fuses. Replace any blown fuses with the appropriate rating to prevent further issues. This simple step can save time and effort in troubleshooting more complex problems.

Finally, verify the operation of electrical accessories. Ensure that all lights, gauges, and other devices function properly. This not only enhances the safety of your vessel but also contributes to a more enjoyable experience on the water.

Cooling System Care

Maintaining the cooling system is essential for the efficient operation of marine engines. Proper care ensures optimal performance and longevity, preventing overheating and potential damage.

Regular maintenance should include the following tasks:

- Inspecting coolant levels and topping off as necessary.

- Checking for leaks in hoses and connections.

- Cleaning the cooling passages to remove any debris or buildup.

- Flushing the system periodically to maintain clear flow.

- Replacing worn or damaged components promptly.

By adhering to these guidelines, you can significantly enhance the reliability of the cooling system, ensuring that your engine operates smoothly under various conditions.

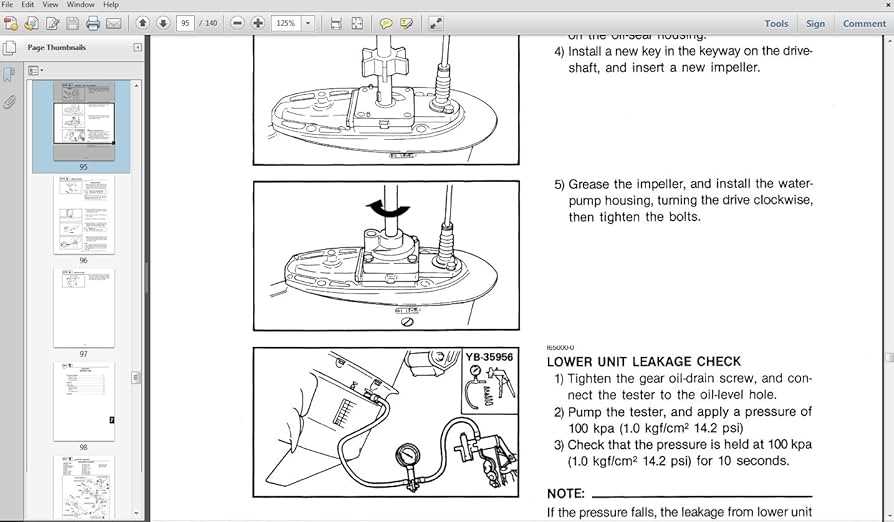

Propeller and Gearbox Maintenance

Regular upkeep of the propeller and gearbox is essential for ensuring optimal performance and longevity of marine engines. Proper care prevents issues that may arise from wear and tear, ultimately enhancing efficiency and reliability during operation.

To maintain these components effectively, it is important to follow a systematic approach that includes inspection, cleaning, and timely repairs. Below is a table summarizing key maintenance tasks:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every Use | Check for visible damage, corrosion, or debris on the propeller and gearbox. |

| Cleaning | Monthly | Remove any marine growth, dirt, or oil buildup to maintain performance. |

| Lubrication | Seasonally | Ensure proper lubrication of moving parts to reduce friction and wear. |

| Gear Oil Change | Annually | Replace the gear oil to maintain optimal functioning and prevent overheating. |

| Propeller Replacement | As Needed | Replace damaged or bent propellers to ensure efficient thrust and reduce strain on the engine. |

By adhering to this maintenance schedule, you can significantly enhance the reliability and efficiency of your marine equipment, ensuring smoother navigation and extended operational life.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance on any marine engine. Taking the necessary precautions helps prevent accidents and injuries, allowing for a smooth and efficient process. Adopting a proactive approach to safety can make all the difference in protecting both the technician and the equipment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. Items such as safety goggles, gloves, and ear protection shield against potential hazards, such as sharp objects and loud noises. Proper attire also includes non-slip footwear to prevent slips and falls, particularly in a workshop environment.

Work Area Organization

A well-organized workspace minimizes the risk of accidents. Keeping tools and materials in designated areas helps prevent tripping hazards and allows for efficient workflow. Additionally, ensuring good ventilation in the work area reduces the risk of inhaling harmful fumes during maintenance activities.

Recommended Service Intervals

Regular maintenance is crucial for ensuring the longevity and optimal performance of your marine engine. Establishing a consistent service schedule helps prevent potential issues and keeps the equipment in top condition.

Routine Checks

It is advisable to perform basic inspections every 100 hours of operation or at least once a season. This includes checking the fuel system, inspecting the cooling system, and ensuring that all safety features are functioning correctly. Additionally, monitoring oil levels and replacing filters are essential steps in maintaining engine health.

Comprehensive Maintenance

A more thorough examination should be conducted every 200 to 300 hours of use. This should involve a complete system check, replacing any worn parts, and addressing any signs of corrosion. Staying proactive with these intervals can save significant costs associated with major repairs in the future.

Upgrading Parts and Accessories

Enhancing your vessel’s performance and functionality can significantly improve your boating experience. By investing in quality components and add-ons, you can achieve better efficiency, reliability, and comfort on the water.

Consider the following upgrades:

- Propellers: Upgrading to a high-performance propeller can increase speed and fuel efficiency.

- Battery Systems: Opt for advanced battery technologies to enhance power and longevity.

- Navigation Tools: Incorporate modern GPS and sonar systems for improved navigation and safety.

- Fuel Systems: Installing high-efficiency fuel injectors can optimize engine performance.

- Seating and Comfort: Invest in ergonomic seating to enhance comfort during long outings.

Each of these enhancements can contribute to a more enjoyable and efficient boating experience. Assess your needs and consult with professionals to select the best options for your specific situation.