Comprehensive Guide to Yamaha 150 Outboard Repair

Proper upkeep of marine propulsion systems is essential for ensuring optimal performance and longevity. Understanding the intricacies of engine mechanics and systems can greatly enhance the efficiency of your vessel. This section serves as a comprehensive resource, offering detailed insights into various maintenance procedures and troubleshooting techniques.

With a focus on practical solutions, the guide provides step-by-step instructions for common challenges faced by boat owners. From routine inspections to advanced repairs, this manual equips you with the knowledge to address issues confidently and effectively. Whether you’re a seasoned technician or a novice enthusiast, mastering these skills will contribute to a more enjoyable experience on the water.

By delving into this resource, you’ll gain a deeper appreciation for the craftsmanship involved in marine engines. Emphasizing safety and precision, the information here is designed to empower you, enabling successful management of your vessel’s engine and associated systems.

Common Issues with Yamaha 150 Engines

When it comes to marine power units, certain challenges tend to arise frequently, impacting performance and reliability. Understanding these typical complications can aid in timely diagnosis and maintenance, ensuring smooth operation during your outings on the water.

Overheating is a prevalent issue that can stem from a variety of sources, including clogged cooling passages or a malfunctioning water pump. Regular checks of the cooling system can help prevent this problem from escalating and causing severe damage.

Fuel delivery problems often manifest as rough idling or difficulty starting. These issues may be linked to clogged filters or malfunctioning fuel pumps. Ensuring that fuel lines and filters are clean can enhance engine efficiency and responsiveness.

Electrical system failures can also be a headache for boaters. Common symptoms include failure to start or intermittent power loss. Regular inspection of the battery, connections, and wiring can mitigate these concerns and prolong the lifespan of the ignition system.

Unusual noises during operation may indicate mechanical wear or damage. Pay attention to any knocking or grinding sounds, which could suggest issues with internal components. Addressing these symptoms promptly can prevent more significant repairs down the line.

By being aware of these frequent challenges, you can take proactive steps to maintain the performance and longevity of your marine engine, ensuring enjoyable and trouble-free experiences on the water.

Essential Tools for Repairs

Effective maintenance and troubleshooting require a well-equipped workspace. The right instruments not only streamline the process but also enhance safety and efficiency. Below are some fundamental items that are indispensable for any enthusiast looking to undertake service tasks.

- Socket Set: A comprehensive socket set is crucial for loosening and tightening various fasteners.

- Wrenches: Both adjustable and fixed wrenches are necessary for dealing with different sizes of bolts and nuts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is essential for accessing various components.

- Multimeter: This tool is invaluable for diagnosing electrical issues, measuring voltage, and checking continuity.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts.

- Torque Wrench: Ensuring that fasteners are tightened to the correct specifications helps prevent damage and maintain performance.

- Oil and Fluid Extractor: This tool facilitates the safe removal of fluids without spills, ensuring a clean workspace.

By having these basic instruments on hand, individuals can effectively address a range of tasks, from routine maintenance to more complex diagnostics. Proper preparation is key to achieving successful outcomes.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your marine engine. Following a systematic approach can help prevent issues and maintain functionality throughout the boating season.

1. Inspection of Components: Begin by examining all key elements, including fuel lines, connections, and the cooling system. Look for signs of wear, corrosion, or leaks. Addressing these concerns early can prevent more significant problems down the line.

2. Fluid Checks: Regularly check the levels of engine oil, coolant, and fuel. Ensure that each fluid meets manufacturer specifications. Replace fluids that are dirty or degraded, as this can enhance engine performance and efficiency.

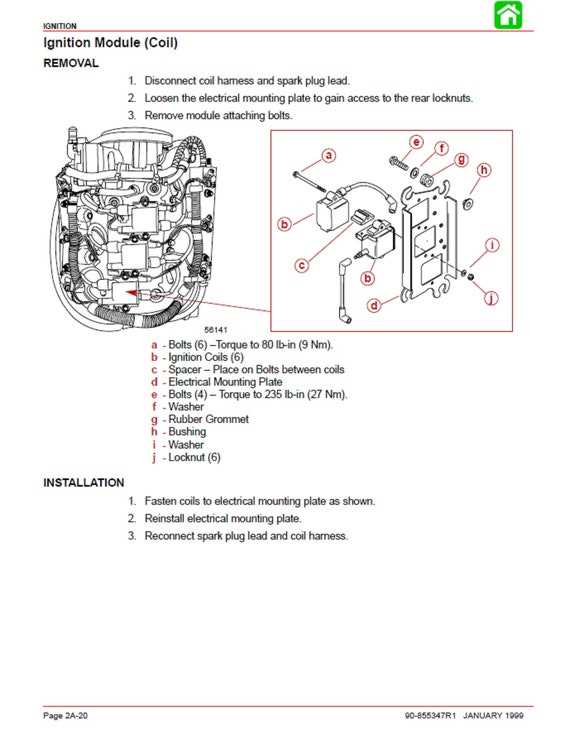

3. Spark Plug Maintenance: Remove and inspect spark plugs for wear and deposits. Clean or replace them as necessary to ensure proper ignition and reduce fuel consumption. A well-maintained ignition system contributes to smoother operation.

4. Propeller Examination: Inspect the propeller for damage, such as dents or bends. A damaged propeller can lead to reduced efficiency and performance. Clean the propeller and ensure it is securely fastened before each outing.

5. Battery Care: Check battery terminals for corrosion and ensure that connections are tight. Keep the battery charged and replace it if it shows signs of deterioration. A reliable power source is vital for starting and operating your engine smoothly.

6. Routine Cleaning: Regularly clean the exterior of the engine and its components. Remove debris and salt buildup to prevent corrosion. A clean engine not only looks better but also runs more efficiently.

By adhering to these maintenance procedures, you can ensure that your marine engine operates at peak efficiency and remains reliable for all your aquatic adventures.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues in marine engines can significantly enhance performance and reliability. This section focuses on common symptoms, diagnostic methods, and effective solutions to restore proper functionality.

Common Symptoms of Electrical Issues

Owners may experience a variety of signs indicating electrical malfunctions. Recognizing these early can prevent further complications.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Dead battery or faulty connections | Check battery voltage and clean terminals |

| Flickering lights | Loose wiring or grounding issues | Inspect and tighten connections |

| Warning alarms sounding | Overheating or low oil pressure | Inspect coolant levels and oil pressure |

Diagnostic Techniques

Utilizing proper diagnostic techniques is essential for effective troubleshooting. Begin with visual inspections and utilize multimeters to check voltage levels throughout the system.

Fuel System Inspection Techniques

Thorough evaluation of the fuel system is essential for ensuring optimal performance and longevity of marine engines. This process involves a series of systematic checks to identify potential issues that could hinder fuel delivery and efficiency. Proper inspection techniques not only help in detecting problems early but also facilitate effective maintenance practices.

Visual Examination

Begin with a detailed visual inspection of the fuel components. Look for any signs of wear, corrosion, or damage to the lines, connectors, and filters. Pay close attention to leaks, as even minor drips can indicate underlying issues. A clean and organized system is a sign of proper maintenance and can enhance the overall reliability of the vessel.

Pressure Testing

Conducting a pressure test is vital for assessing the integrity of the fuel system. Utilizing a pressure gauge, check for adequate pressure throughout the system. Any significant drop may signal leaks or blockages that require immediate attention. Regular pressure testing can prevent costly repairs and ensure the engine operates efficiently.

Gearbox and Propeller Maintenance

Regular upkeep of the transmission and propulsive components is essential for optimal performance and longevity. Proper maintenance helps prevent wear, improves efficiency, and ensures a smooth operation in various conditions.

Key aspects to focus on include:

- Inspection: Routinely check for signs of damage or wear. Look for any unusual sounds during operation.

- Lubrication: Ensure all moving parts are adequately lubricated to minimize friction and heat buildup.

- Cleaning: Keep the gearbox and propeller free from debris and marine growth to maintain efficiency.

When it comes to the propeller, attention should be given to the following:

- Check Blades: Examine for nicks, dents, or cracks that may affect performance.

- Alignment: Ensure the propeller is properly aligned with the shaft to prevent vibration and damage.

- Pitch Measurement: Verify that the pitch is consistent with specifications for optimal thrust.

By adhering to these maintenance practices, operators can significantly extend the lifespan of their transmission and propulsive systems, ensuring reliable performance for years to come.

Identifying and Fixing Overheating

Overheating in marine engines can lead to severe damage if not addressed promptly. Recognizing the signs of excessive temperature and understanding how to mitigate this issue is essential for maintaining performance and longevity. This section outlines the key indicators of overheating and provides steps to rectify the problem effectively.

Common symptoms of elevated temperatures include:

| Indicator | Description |

|---|---|

| Temperature Gauge | Reading above normal operating range. |

| Steam or Smoke | Visible steam or smoke from the engine compartment. |

| Unusual Noises | Strange sounds indicating stress on engine components. |

| Loss of Power | Decreased acceleration and overall engine performance. |

To address overheating, follow these steps:

- Check the cooling system for blockages, including hoses and filters.

- Inspect the water intake for debris or damage.

- Ensure that the thermostat is functioning correctly.

- Monitor the coolant levels and replenish as necessary.

- Consider consulting a professional if the issue persists.

By identifying and resolving overheating promptly, you can help ensure the engine operates smoothly and efficiently, avoiding costly repairs in the future.

Best Practices for Storage

Proper storage techniques are essential for maintaining the longevity and performance of marine engines. Implementing the right strategies ensures that equipment remains in optimal condition during periods of inactivity, safeguarding against environmental factors and potential damage.

Preparation Steps

Before storing your marine engine, several key steps should be taken to prepare it adequately. This preparation minimizes the risk of deterioration and mechanical issues when the time comes to use it again.

| Step | Description |

|---|---|

| Cleaning | Thoroughly clean the exterior and any accessible components to remove salt, dirt, and debris. |

| Fuel Stabilization | Add a fuel stabilizer to the tank and run the engine to circulate it throughout the system. |

| Oil Change | Replace the oil and filter to prevent contamination and ensure smooth operation upon restart. |

| Cooling System | Flush the cooling system with fresh water and ensure it is free of any contaminants. |

Storage Environment

Choosing an appropriate environment for storage is crucial. Ideally, equipment should be kept in a dry, temperature-controlled space to prevent corrosion and degradation.

Safety Tips for Repair Work

When engaging in maintenance tasks on marine engines, it’s crucial to prioritize safety. Proper precautions can help prevent accidents and ensure a smooth working environment. Familiarizing yourself with essential guidelines will not only protect you but also extend the life of your equipment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots to safeguard against potential hazards. Ear protection is advisable when using loud tools, while a respirator may be necessary in poorly ventilated areas where fumes are present.

Workspace Organization

Maintain a clean and organized workspace. Remove any unnecessary items that could pose tripping hazards. Keep tools and materials neatly stored to avoid accidents. Ensure good lighting to enhance visibility, making it easier to spot potential dangers while working.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of marine propulsion systems. It aims to provide clarity on various topics to assist users in effectively managing their equipment.

Common Issues and Solutions

- Engine Won’t Start:

- Check the fuel supply.

- Inspect the ignition system.

- Examine the battery condition.

- Overheating:

- Ensure proper water intake.

- Check the thermostat functionality.

- Look for blockages in the cooling system.

- Strange Noises:

- Identify any loose components.

- Listen for signs of wear in the drivetrain.

- Consult a professional if noises persist.

Maintenance Tips

- Regularly inspect fuel and oil levels.

- Replace filters as recommended.

- Clean the exterior to prevent corrosion.

- Store properly during off-seasons.

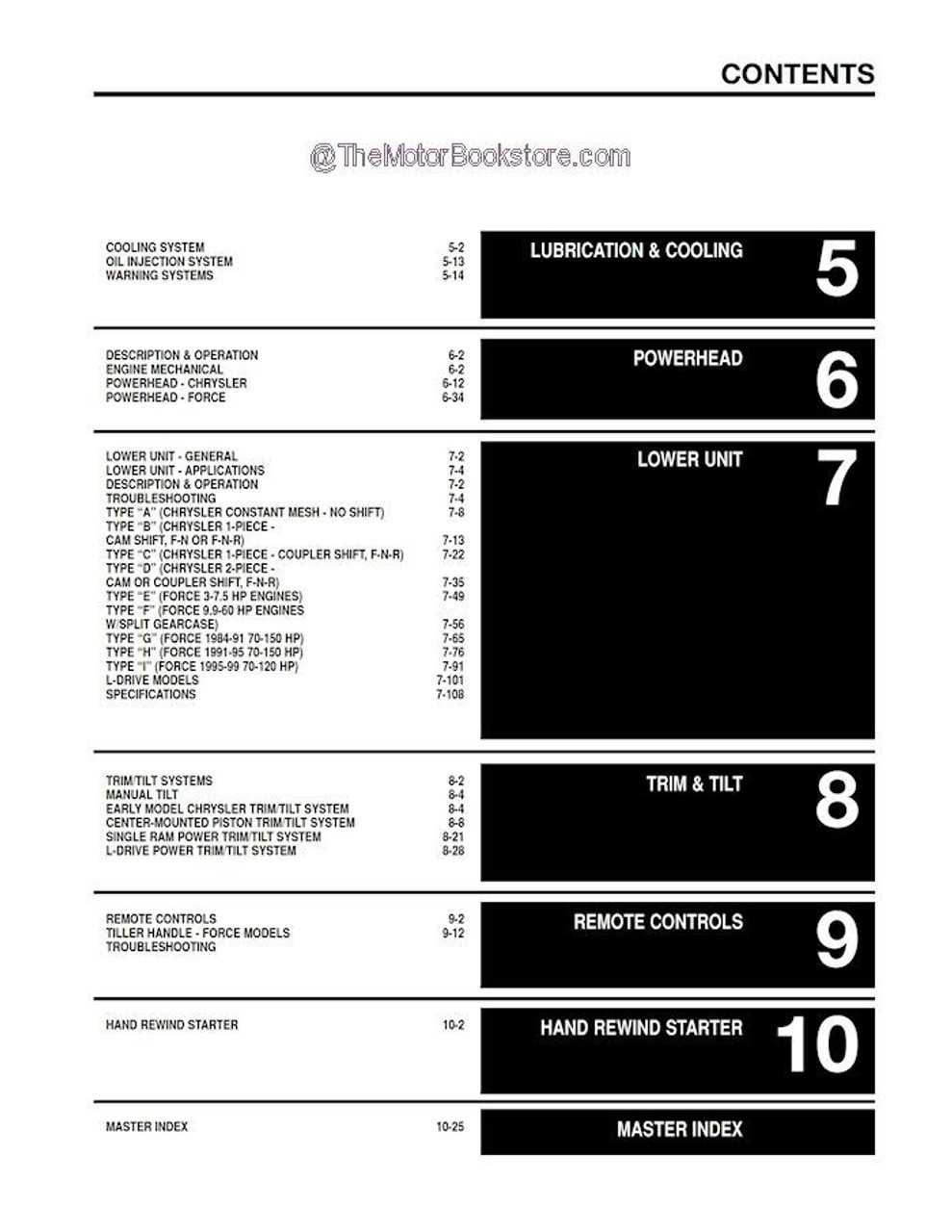

Where to Find Replacement Parts

Locating suitable components for marine engines can be crucial for maintaining performance and reliability. Whether you are addressing a malfunction or performing routine maintenance, having access to the right parts is essential for a smooth operation.

Authorized Dealers and Distributors

One of the most reliable sources for acquiring components is through authorized dealers and distributors. These establishments typically offer genuine products that ensure compatibility and durability.

Online Marketplaces

In addition to local dealers, numerous online platforms provide a vast selection of parts. These websites often feature user reviews and ratings, helping buyers make informed choices.

| Source | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealers | Genuine parts, expert advice | Higher prices |

| Online Marketplaces | Wide variety, competitive pricing | Quality may vary, longer shipping times |

| Local Marine Stores | Immediate access, knowledgeable staff | Limited selection |