Comprehensive Guide to Yamaha TTR 90 Repairs

Ensuring the longevity and optimal performance of your two-wheeled companion is crucial for any enthusiast. A comprehensive resource focused on the intricacies of upkeep can significantly enhance your riding experience. From understanding core components to troubleshooting common issues, this guide serves as a valuable asset for both novice and seasoned riders.

With a detailed approach to diagnostics, you will be equipped to tackle various challenges that may arise. This resource not only covers routine checks but also delves into more complex procedures that can restore functionality and safety. Emphasizing preventative measures and timely interventions, it aims to empower you with the knowledge to confidently manage your vehicle’s requirements.

Whether you’re addressing minor adjustments or preparing for more extensive projects, having access to a structured guide can simplify the process. Explore this indispensable tool to enhance your maintenance skills and ensure your machine operates at its best.

Overview of Yamaha TTR 90

This section provides an insight into a popular off-road two-wheeled vehicle designed for both beginners and experienced riders. It emphasizes the key features, specifications, and overall performance that contribute to its appeal.

The vehicle is known for its:

- Compact design, making it suitable for younger riders and those new to off-roading.

- Robust build quality, ensuring durability on rugged terrains.

- Lightweight frame, allowing for easy handling and maneuverability.

Some notable characteristics include:

- A reliable engine that provides sufficient power for various riding conditions.

- An adjustable suspension system, enhancing comfort and stability.

- User-friendly controls, making it accessible for riders of all skill levels.

This off-road machine has become a favored choice for enthusiasts seeking an engaging riding experience, blending functionality with enjoyable performance.

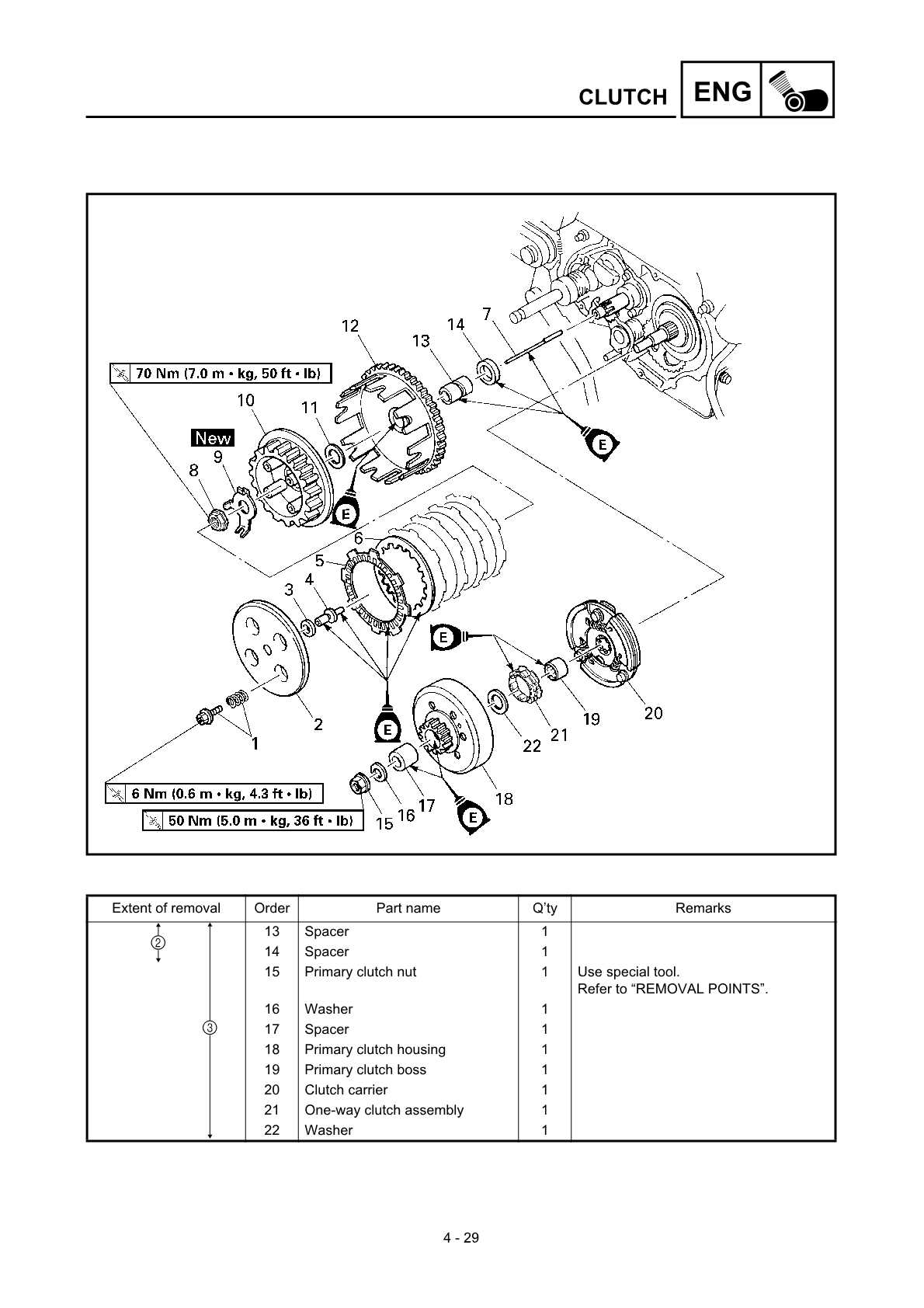

Common Issues and Solutions

Every mechanical device may encounter challenges over time, leading to decreased performance or functionality. Understanding these typical problems and their resolutions is essential for maintaining optimal operation and ensuring longevity.

Starting Difficulties: One prevalent issue is the struggle to start the engine. This may stem from an empty fuel tank, clogged fuel lines, or a weak battery. Checking fuel levels and ensuring proper flow can often resolve this problem. Additionally, testing the battery and replacing it if necessary can restore functionality.

Unusual Noises: Unwanted sounds during operation can indicate underlying mechanical issues. Rattling or grinding noises may signal loose components or worn-out parts. Regular inspections and tightening of bolts, along with timely replacements, are crucial to prevent further damage.

Performance Issues: A noticeable decline in speed or responsiveness can be attributed to several factors, including air filter blockages or carburetor malfunctions. Cleaning or replacing the air filter and ensuring the carburetor is properly adjusted can enhance overall performance significantly.

Braking Problems: Ineffective braking can pose serious safety risks. Worn brake pads or insufficient brake fluid may contribute to this issue. Regularly inspecting the braking system and replacing pads or replenishing fluid as needed can ensure safe stopping capabilities.

By recognizing these common challenges and implementing appropriate solutions, one can maintain the functionality and safety of the machine, allowing for a more enjoyable riding experience.

Essential Tools for Repair

Having the right equipment is crucial when it comes to maintaining and restoring a two-wheeled vehicle. A well-equipped workspace not only enhances efficiency but also ensures that tasks are performed safely and effectively. Here are some key instruments that will aid in the upkeep of your machine.

Basic Hand Tools

Every technician should possess a set of fundamental hand tools. Items such as wrenches, pliers, and screwdrivers are indispensable for various tasks, including tightening fasteners and adjusting components. Socket sets are particularly useful for accessing hard-to-reach bolts, while torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage.

Specialized Equipment

In addition to basic hand tools, specialized equipment can greatly facilitate more complex tasks. Multimeters are essential for diagnosing electrical issues, allowing you to measure voltage, current, and resistance. Furthermore, chain tools are invaluable for maintenance and repair of drive systems, ensuring optimal performance.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your two-wheeled vehicle. Regular upkeep not only enhances efficiency but also prevents potential issues down the line. Follow these detailed steps to maintain your machine effectively.

| Task | Frequency | Tools Needed | Steps |

|---|---|---|---|

| Check Oil Level | Every 500 km | Dipstick, Oil |

|

| Inspect Tires | Every 1000 km | Tire Pressure Gauge |

|

| Clean Air Filter | Every 1500 km | Wrench, Clean Cloth |

|

| Lubricate Chain | Every 800 km | Chain Lubricant |

|

| Check Brake Functionality | Monthly | None |

|

Engine Troubleshooting Techniques

Troubleshooting engine issues requires a systematic approach to identify and resolve common problems that may affect performance. By understanding the underlying mechanics, one can efficiently diagnose faults and implement effective solutions.

Start with Basic Checks: Before delving into complex repairs, ensure that basic components are functioning correctly. Check the fuel supply, air filter, and spark plug for signs of wear or blockage. These elements play a crucial role in engine operation.

Utilize Diagnostic Tools: Employing diagnostic tools can significantly aid in pinpointing issues. Compression testers and multimeters provide insights into engine health and electrical systems. Use these tools to measure performance metrics and detect abnormalities.

Observe Engine Behavior: Pay attention to how the engine behaves during operation. Unusual noises, vibrations, or changes in performance can signal underlying problems. Note any irregularities to assist in the diagnostic process.

Consult Resources: Gathering information from various resources, such as forums or technical articles, can provide additional perspectives on troubleshooting methods. Other enthusiasts’ experiences can offer valuable insights into similar issues.

Document Your Findings: Keeping a record of observations and changes made during the troubleshooting process can help track progress and identify recurring problems. Documentation serves as a useful reference for future maintenance and repairs.

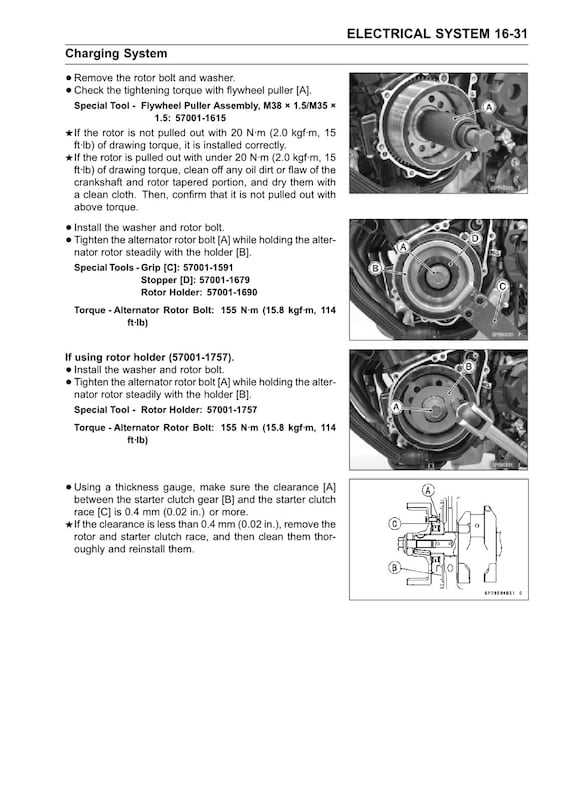

Electrical System Inspection Tips

Ensuring the functionality of the electrical components in your vehicle is crucial for optimal performance. Regular checks can prevent potential issues that might affect overall operation. This section provides practical insights to help you effectively assess the electrical setup.

Visual Examination

Begin with a thorough visual inspection of the wiring and connectors. Look for signs of wear, corrosion, or fraying. Damaged wires can lead to shorts or intermittent failures. Ensure all connections are secure and free from dirt or moisture that may compromise electrical conductivity.

Testing Components

Use a multimeter to measure voltage and resistance across various components. This step is essential for diagnosing problems accurately. Check the battery voltage to ensure it meets the manufacturer’s specifications. Additionally, testing switches and relays can identify potential faults before they escalate into more significant issues.

Replacing Common Wear Parts

Maintaining the longevity and performance of a two-wheeled vehicle often requires attention to components that are prone to wear over time. Regular inspection and timely replacement of these essential elements can significantly enhance the overall functionality and safety of the machine.

Key Components to Monitor

- Brake Pads: Over time, brake pads can wear down, affecting stopping power. Regular checks ensure optimal performance.

- Chain and Sprockets: The chain and sprockets endure considerable strain and should be inspected for signs of elongation or damage.

- Air Filter: A clean air filter is crucial for engine performance. Replacing it periodically prevents dirt from entering the engine.

- Spark Plug: The spark plug is vital for efficient ignition. A worn spark plug can lead to starting issues and decreased fuel efficiency.

- Tires: Inspecting tires for tread wear and proper inflation is essential for safety and handling.

Replacement Tips

- Always consult the specifications for the correct parts and tools required for replacements.

- Use quality replacement parts to ensure compatibility and reliability.

- Keep a maintenance log to track replacements and inspections.

- Seek professional assistance if uncertain about performing any replacements.

Suspension Adjustments and Repairs

The performance and comfort of a two-wheeled vehicle greatly depend on its suspension system. Proper tuning and maintenance of this crucial component ensure optimal handling and rider safety. Understanding how to modify and fix suspension elements can enhance the riding experience significantly.

Adjustments to the suspension should be made based on individual preferences and riding conditions. Below are key considerations for tuning:

- Spring Preload: Adjust the preload to match the rider’s weight and riding style. A stiffer setting may be beneficial for aggressive riding, while a softer setting provides comfort for casual trips.

- Compression Damping: Fine-tune the compression damping to control how quickly the suspension absorbs impacts. Increasing damping can improve stability over rough terrain.

- Rebound Damping: Ensure the rebound damping is adjusted to prevent the suspension from bouncing back too quickly after compression. This adjustment aids in maintaining traction and stability.

Regular inspection and maintenance of suspension components are essential. Here are common issues to look for:

- Leakage: Check for any signs of oil leakage from forks or shocks, which can indicate worn seals or damage.

- Worn Bushings: Inspect bushings for wear, as degraded bushings can lead to poor handling and noise.

- Alignment: Ensure that the suspension components are properly aligned to avoid uneven wear and performance issues.

In the event of damage or failure, replacement parts should be sourced from reliable suppliers to maintain quality and performance. Following these guidelines can help ensure a smooth and enjoyable ride.

Cleaning and Care Procedures

Maintaining the performance and longevity of your two-wheeled vehicle involves regular cleaning and care routines. These procedures help prevent wear and tear while ensuring optimal functionality. Below are essential steps to keep your machine in top condition.

Start by gathering the necessary supplies:

- Soft cloths or rags

- Bucket of water

- Non-corrosive soap or detergent

- Brush with soft bristles

- Chain lubricant

- Protective gloves

Follow these steps for effective cleaning:

- Preparation: Park the vehicle on a flat surface and ensure the engine is cool. Remove any loose dirt or debris.

- Washing: Mix soap with water in the bucket. Use the brush to gently scrub the exterior, starting from the top and working downwards.

- Rinsing: Rinse the surface with clean water to remove soap residue. Avoid using high-pressure water jets, as they may damage components.

- Drying: Wipe the vehicle with soft cloths to prevent water spots and corrosion.

- Chain Maintenance: Clean the chain with a brush to remove grime. Apply lubricant to keep it functioning smoothly.

Regular inspections should also be part of your care routine:

- Check tire pressure and tread for wear.

- Inspect brake pads for sufficient thickness.

- Ensure all lights and indicators are operational.

By implementing these cleaning and maintenance procedures, you will enhance the performance and durability of your machine, allowing for a more enjoyable riding experience.

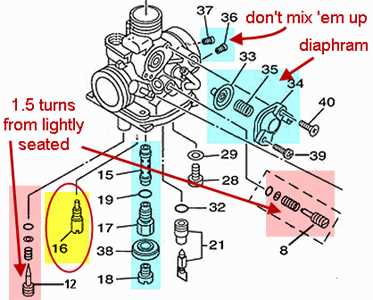

Fuel System Maintenance Essentials

Ensuring optimal performance of the fuel delivery system is vital for the overall functionality of the vehicle. Regular attention to this area can prevent issues such as poor starting, stalling, and reduced efficiency. Below are key practices to maintain the fuel system effectively.

- Inspect Fuel Lines: Regularly check for any signs of wear, leaks, or damage. Replace any compromised lines to maintain proper fuel flow.

- Clean or Replace Fuel Filter: A clogged filter can hinder fuel delivery. Clean or replace it at intervals specified by the manufacturer.

- Examine the Fuel Pump: Ensure that the pump is functioning correctly. Listen for any unusual noises during operation that may indicate malfunction.

- Check Fuel Quality: Use clean and appropriate fuel for the system. Contaminated fuel can lead to severe engine issues.

- Inspect Carburetor or Fuel Injection System: Regular cleaning and tuning are necessary for these components to ensure optimal performance.

By adhering to these essential maintenance practices, you can significantly enhance the reliability and longevity of the fuel delivery system.

Safety Precautions During Repairs

When undertaking maintenance or servicing tasks, it is crucial to prioritize safety. Following established guidelines helps prevent accidents and ensures a smooth process. Proper preparation and awareness of potential hazards contribute significantly to a secure environment while working on mechanical equipment.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Ensure that the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the work area tidy to minimize the risk of slips and falls.

- Disconnect the power source or remove the spark plug before beginning any work on the machinery.

Handling Tools and Equipment

- Use tools that are specifically designed for the tasks at hand.

- Inspect tools regularly for damage or wear before use.

- Store tools properly after use to avoid accidents and facilitate easy access.

- Follow the manufacturer’s instructions for all equipment to ensure safe operation.

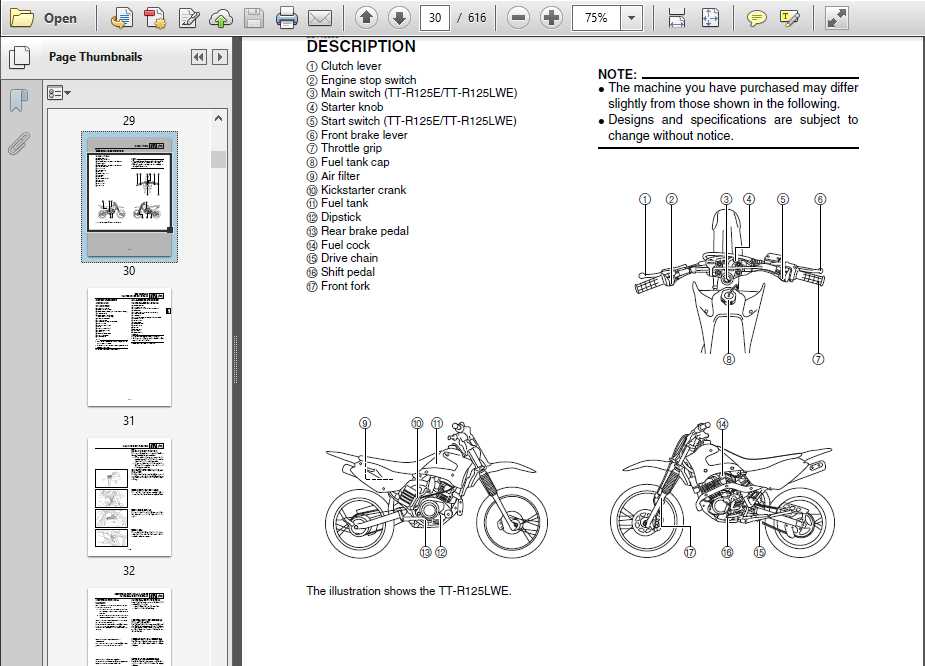

Understanding the Owner’s Manual

The owner’s guide serves as a vital resource for understanding the features and maintenance of your two-wheeled vehicle. It contains essential information that helps you ensure the longevity and performance of your machine. By familiarizing yourself with this document, you can enhance your riding experience and troubleshoot common issues effectively.

Key Components of the Guide

Typically, the manual includes sections on operating instructions, safety precautions, and maintenance schedules. Operating instructions provide insight into the various controls and their functions, allowing you to use your vehicle safely and efficiently. Safety precautions outline critical guidelines to prevent accidents and ensure your well-being while riding.

Maintenance and Troubleshooting

A well-structured manual outlines routine maintenance tasks, such as oil changes and tire pressure checks, that are crucial for optimal performance. Additionally, a troubleshooting section can help identify common problems and offer step-by-step solutions, empowering you to address issues without professional assistance.