Comprehensive Service Repair Guide for Stihl Chainsaw MS170

Ensuring the longevity and optimal performance of your outdoor power equipment requires a comprehensive understanding of its components and functions. This guide provides detailed insights into the various aspects of maintenance, enabling users to effectively address common issues and enhance the overall efficiency of their tools.

Through a systematic approach, you will discover the key techniques for both preventative measures and problem resolution. By familiarizing yourself with the inner workings of your device, you can perform essential tasks that safeguard against wear and tear, ultimately prolonging its lifespan.

This resource serves as a valuable reference for both novice and experienced users. Whether you are looking to conduct routine checks or tackle specific challenges, the information herein is designed to empower you with the knowledge necessary for effective upkeep and troubleshooting. With the right guidance, you can ensure that your equipment remains reliable and ready for any task.

Overview of Stihl MS170 Chainsaw

This section provides a comprehensive insight into a popular model designed for both casual and professional users. With its robust features and reliable performance, this tool is well-suited for a variety of tasks, from pruning branches to cutting firewood. Its compact design enhances maneuverability, making it an excellent choice for those seeking efficiency and ease of use.

Key Features

- Lightweight construction for improved handling.

- Powerful engine that ensures effective cutting.

- Easy-start mechanism for user convenience.

- Automatic lubrication system to maintain chain health.

- Safety features to protect the user during operation.

Applications

- Tree trimming and pruning.

- Firewood preparation.

- Landscaping and garden maintenance.

- DIY projects and home improvement tasks.

Whether you are an enthusiast or a professional, this model offers a blend of power and usability that caters to a wide range of cutting needs.

Common Issues with Stihl MS170

When using power equipment, users often encounter a variety of challenges that can hinder performance. Understanding these frequent problems can help in maintaining efficiency and prolonging the lifespan of the tool. From starting difficulties to operational inconsistencies, recognizing the symptoms early on can lead to timely interventions.

Starting Difficulties

One of the most prevalent issues is trouble with ignition. Users may notice that the engine struggles to start or does not start at all. This could stem from several factors, such as a clogged fuel filter, stale fuel, or a malfunctioning spark plug. Regular checks and maintenance of these components can significantly improve starting reliability.

Power Loss and Stalling

Another common concern is experiencing power loss during operation or abrupt stalling. This may result from a dirty air filter, improper fuel mixture, or issues within the carburetor. Ensuring that the air intake is clean and that fuel is mixed correctly can help restore optimal performance and prevent frustrating interruptions.

Essential Tools for Repairs

When it comes to maintaining and restoring outdoor power equipment, having the right set of tools is crucial. A well-equipped toolbox not only facilitates efficient work but also ensures that every task can be completed with precision. Whether you are addressing minor adjustments or more significant issues, understanding which instruments are necessary will enhance your overall experience.

Basic Tools

To begin with, a few fundamental instruments should be present in every maintenance kit. A reliable set of screwdrivers, including both flat-head and Phillips, will allow you to access various components easily. Additionally, a wrench set is essential for loosening or tightening bolts securely. Don’t forget to include a hammer for any necessary adjustments or alignments.

Specialized Equipment

In addition to the basics, certain specialized tools can significantly streamline your efforts. A chain file is important for keeping cutting edges sharp and efficient. Moreover, a compression tester can help assess engine health, ensuring optimal performance. Lastly, consider a workbench with a sturdy vise; this setup provides stability and ease of access while working on components.

Step-by-Step Maintenance Guide

Regular upkeep of your power tool is essential for optimal performance and longevity. This guide outlines a systematic approach to maintaining your equipment, ensuring it operates smoothly and efficiently. By following these steps, you can prevent potential issues and enhance the overall functionality of your device.

Essential Tools and Safety Precautions

Before starting any maintenance tasks, gather the necessary tools, including a wrench, screwdriver, and cleaning supplies. Ensure you wear appropriate safety gear, such as gloves and goggles, to protect yourself during the process. Always disconnect the power source before performing any maintenance activities to avoid accidents.

Routine Checks and Cleaning

Begin with a thorough inspection of the unit. Check for any visible wear or damage, paying close attention to the cutting elements and air filters. Clean the exterior and internal components with a soft brush or cloth to remove debris and dirt. Regularly replacing the air filter and sharpening the cutting components can significantly enhance performance and extend the life of your equipment.

Remember that a well-maintained tool not only performs better but also ensures your safety during use. Following these steps diligently will keep your device in peak condition.

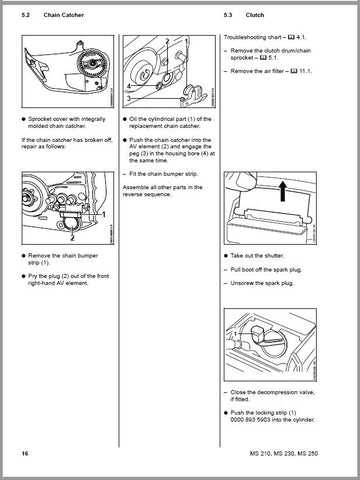

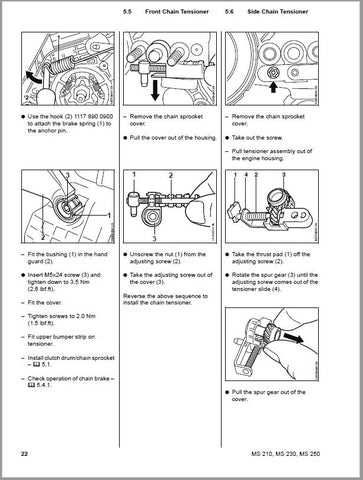

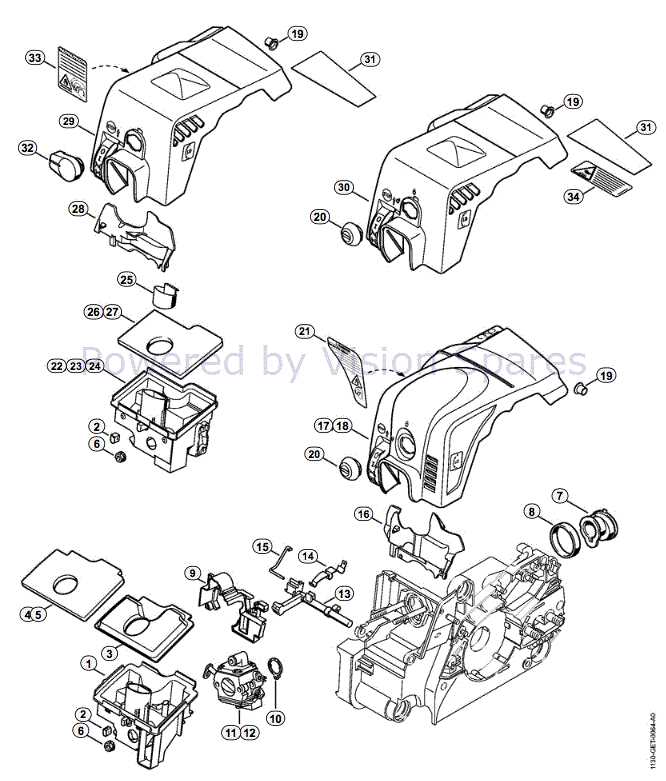

Replacing the Chainsaw Chain

Changing the cutting element of your power tool is essential for maintaining its performance and safety. Over time, the chain can wear out, leading to reduced efficiency and potential hazards. This section outlines the steps necessary to effectively replace the cutting component, ensuring optimal functionality.

Tools Required

- New cutting chain

- Wrench or screwdriver

- Protective gloves

- Safety goggles

Steps to Replace the Cutting Element

- Ensure the tool is powered off and disconnect from any power source.

- Remove the side cover by loosening the screws with the wrench or screwdriver.

- Take out the worn cutting element carefully from the guide bar.

- Position the new chain around the guide bar, ensuring it follows the correct path.

- Reattach the side cover, securing it with the screws tightly.

- Check the tension of the new chain and adjust as necessary.

Regular maintenance, including chain replacement, is key to prolonging the lifespan of your equipment and ensuring safe operation. Always consult the manufacturer’s guidelines for specific details related to your model.

How to Clean the Air Filter

Maintaining optimal airflow is crucial for the performance of your equipment. A clean air filter ensures that the engine receives sufficient air, improving efficiency and extending its lifespan. Regular cleaning of the filter not only enhances performance but also helps prevent potential damage caused by dirt and debris accumulation.

Materials Needed

- Clean, dry cloth

- Soft brush

- Soapy water

- Bucket

- Air compressor (optional)

Cleaning Steps

- Remove the air filter from the housing. Consult your user guide for specific instructions.

- Inspect the filter for any tears or damage. If it is damaged, replace it with a new one.

- Use a soft brush to gently remove loose dirt and debris from the filter surface.

- In a bucket, mix warm water with a mild detergent. Soak the filter in this solution for a few minutes.

- Gently scrub the filter with a soft cloth to remove any stubborn grime.

- Rinse the filter thoroughly under clean running water to remove all soap residue.

- If available, use an air compressor to blow out any remaining water and dirt. Ensure the filter is completely dry before reinstallation.

- Reinstall the air filter securely back into the housing.

By following these steps, you can ensure that your equipment continues to operate efficiently. Regular attention to the air filter will contribute to better overall performance and longevity.

Diagnosing Engine Performance Problems

Identifying issues related to engine performance is essential for ensuring optimal functionality and longevity of your equipment. Various symptoms can indicate underlying problems, which require careful observation and systematic troubleshooting to resolve effectively.

Common Symptoms of Engine Issues

- Loss of power during operation

- Unusual vibrations or noise

- Difficulty starting the engine

- Excessive smoke or unusual exhaust color

- Inefficient fuel consumption

Troubleshooting Steps

- Check the fuel quality and ensure it is fresh and appropriate for the engine.

- Inspect the air filter for clogs and replace it if necessary.

- Examine spark plugs for wear and clean or replace them as needed.

- Assess the carburetor for blockages or improper adjustments.

- Look for leaks in fuel lines or connections that may affect performance.

Following these steps can help pinpoint the cause of performance issues, leading to effective solutions and enhanced engine operation.

Fuel System Troubleshooting Tips

Ensuring optimal performance of your equipment requires understanding its fuel system. Common issues can arise, leading to inefficient operation or complete failure. By following some basic troubleshooting steps, you can identify and resolve problems effectively.

Identifying Fuel Flow Issues

Start by checking the fuel supply. Ensure that the tank is filled with the appropriate mixture and that there are no blockages in the fuel lines. Inspect the fuel filter for clogs, as a dirty filter can restrict flow and cause starting issues. Additionally, examine the fuel lines for cracks or damage that might prevent proper circulation.

Examining Carburetor Functionality

The carburetor plays a crucial role in the air-fuel mixture. If the engine runs poorly or stalls, it may require adjustment. Check for leaks around the gaskets and ensure that the needle and seat are functioning correctly. Cleaning the carburetor can also help remove any residue that may hinder performance. Regular maintenance of this component is essential to maintain efficiency.

Checking and Adjusting the Carburetor

Ensuring optimal performance of your engine requires regular examination and fine-tuning of the fuel delivery system. The carburetor plays a critical role in mixing air and fuel, influencing the efficiency and power of the engine. Proper adjustments can enhance functionality, reduce emissions, and improve overall operation.

Tools Needed

Before starting the adjustment process, gather the necessary tools: a screwdriver, a tachometer, and a clean cloth. These will assist in making precise alterations and ensuring the engine runs smoothly.

Steps for Adjustment

Begin by starting the engine and letting it warm up to operating temperature. Once warmed, locate the adjustment screws–typically labeled for low and high-speed settings. Use the screwdriver to turn these screws gently. Clockwise adjustments generally lean the mixture, while counterclockwise increases fuel flow.

Monitor the engine’s response to adjustments, aiming for a smooth idle and strong acceleration. If the engine stalls or runs unevenly, make incremental changes until the desired performance is achieved. Regular checks will ensure the longevity and efficiency of the equipment.

Inspecting the Spark Plug Condition

Regular assessment of the ignition component is crucial for optimal engine performance. This part plays a vital role in the combustion process, and its condition can significantly affect starting, efficiency, and overall functionality. Identifying any wear or damage can help in maintaining peak operation.

Signs of Wear and Damage

When examining the ignition component, look for the following indicators:

- Carbon Deposits: Black, sooty buildup can lead to misfiring.

- Burnt Electrodes: A worn or eroded electrode can impair spark generation.

- Cracks or Chips: Physical damage can disrupt the ignition process.

- Color of Insulator: A white insulator indicates overheating, while a brownish hue suggests normal operation.

Steps for Inspection

To thoroughly check the ignition component, follow these steps:

- Remove the ignition component using the appropriate tool.

- Clean any debris from the area before inspection.

- Visually inspect for signs of wear or damage as listed above.

- Test the gap between the electrodes using a feeler gauge to ensure it meets specifications.

- Replace the component if any significant issues are found.

Regular checks of the ignition component are essential for maintaining engine reliability and performance. By staying vigilant about its condition, you can prevent potential issues before they escalate.

Safety Precautions During Repair

When working on power equipment, ensuring personal safety should always be the top priority. Adopting proper precautions can significantly reduce the risk of injury or accidents. This section outlines essential guidelines that should be followed to maintain a safe working environment while conducting maintenance tasks.

Always Wear Protective Gear: Equip yourself with appropriate safety equipment, including gloves, goggles, and sturdy footwear. This protective attire is vital in shielding you from potential hazards such as sharp components or flying debris.

Work in a Well-Ventilated Area: Ensure that your workspace is adequately ventilated to prevent inhalation of harmful fumes or dust. If necessary, utilize exhaust fans or open windows to facilitate airflow.

Disconnect Power Sources: Before starting any disassembly or inspection, make sure to disconnect all power sources. This step is crucial to avoid unintentional activation of the equipment, which could lead to severe injuries.

Organize Your Tools: Keep your tools and components organized to minimize distractions and enhance focus. A clutter-free workspace reduces the risk of accidents and helps you locate necessary tools quickly.

Follow Manufacturer Instructions: Always refer to the guidelines provided by the manufacturer. Adhering to these instructions ensures that you understand the specific requirements and precautions needed for safe handling of the equipment.

Keep the Area Clear: Maintain a clean and tidy workspace by removing unnecessary items. This practice not only promotes safety but also allows for better concentration on the task at hand.

By following these precautions, you can create a safe environment that minimizes risks associated with maintenance activities. Prioritizing safety is essential for both your well-being and the proper functioning of the equipment.

Finding Genuine Stihl Replacement Parts

Ensuring the longevity and efficiency of your equipment relies heavily on using authentic components. Identifying and sourcing these original parts can enhance performance and reliability, providing peace of mind during operation. This section delves into effective strategies for acquiring quality replacements.

Why Choose Authentic Components?

Opting for genuine pieces offers numerous advantages:

- Quality Assurance: Original components are manufactured to meet strict standards, ensuring optimal functionality.

- Compatibility: These parts are designed to fit seamlessly with your equipment, reducing the risk of malfunction.

- Warranty Protection: Using authentic components helps maintain any existing warranties on your equipment.

Where to Find Authentic Parts

Locating genuine components can be straightforward if you know where to look:

- Authorized Dealers: Visit certified retailers who specialize in your equipment brand.

- Official Websites: Utilize online platforms associated with the manufacturer for direct purchases.

- Reputable Repair Shops: Seek assistance from service centers that are known for using authentic parts.

By prioritizing the use of original components, you ensure the reliability and performance of your equipment for years to come.

Understanding the Warranty Terms

When purchasing power equipment, it’s crucial to be aware of the warranty provisions that protect your investment. Warranty terms serve as a promise from the manufacturer regarding the quality and durability of the product, ensuring that any defects or issues arising within a specified timeframe will be addressed without additional cost to the consumer.

Key Components of Warranty Agreements

A comprehensive warranty typically includes various components that define the extent of coverage, exclusions, and obligations of both the manufacturer and the purchaser. Understanding these elements can help users navigate any potential claims effectively.

| Component | Description |

|---|---|

| Duration | The length of time the warranty is valid, often measured from the date of purchase. |

| Coverage | Details on what parts and labor are included under warranty provisions. |

| Exclusions | Specific circumstances or damages that are not covered, such as misuse or normal wear and tear. |

| Claims Process | Steps to take when filing a warranty claim, including necessary documentation. |

Importance of Keeping Documentation

Maintaining proper records, such as receipts and warranty cards, is vital for ensuring that claims can be processed smoothly. Without this documentation, securing warranty service can become challenging, potentially leaving the user without the benefits they rightfully deserve.