Comprehensive Guide to Yamaha YZF600R Thundercat Repair

Maintaining a high-performance two-wheeler is essential for ensuring optimal functionality and longevity. This section offers an in-depth look at essential procedures, troubleshooting techniques, and best practices for riders aiming to keep their machines in peak condition. Proper upkeep not only enhances performance but also ensures safety on the road.

For enthusiasts and technicians alike, a detailed approach to service can significantly extend the lifespan of the vehicle. The guide will cover critical areas such as engine care, electrical system checks, and routine inspections. Each aspect plays a vital role in preserving the machine’s reliability and efficiency.

Whether you’re an experienced mechanic or a novice rider, this resource is designed to equip you with the knowledge needed to handle various maintenance tasks confidently. By following the outlined steps, you can navigate the complexities of servicing your vehicle effectively and with ease.

This section provides an overview of essential knowledge regarding your motorcycle. Understanding its components and maintenance requirements ensures optimal performance and longevity. Here, we will explore several key aspects that every rider should be familiar with.

Key Components of Your Bike

Familiarizing yourself with the primary parts of your motorcycle is crucial. Below are some critical components:

- Engine: The heart of the motorcycle.

- Transmission: Manages gear shifting.

- Brakes: Essential for safety and control.

- Suspension: Impacts ride comfort and handling.

- Electrical System: Powers lights and instruments.

Routine Maintenance Tips

Regular upkeep can enhance performance and prevent issues. Consider these maintenance practices:

- Check oil levels frequently.

- Inspect tire pressure and tread.

- Clean and adjust the chain.

- Examine brake fluid and pads.

- Ensure lights and signals function.

Troubleshooting Common Issues

Being able to identify problems early can save time and money. Here are typical issues to watch for:

- Starting difficulties: Check the battery and starter.

- Unusual noises: Investigate the engine and transmission.

- Brake performance: Look for worn pads or low fluid.

- Electrical failures: Test fuses and wiring.

- Handling problems: Assess suspension and tire condition.

Upgrading Your Ride

Enhancements can improve both aesthetics and performance. Consider these upgrade options:

- Performance exhaust systems.

- Aftermarket suspension components.

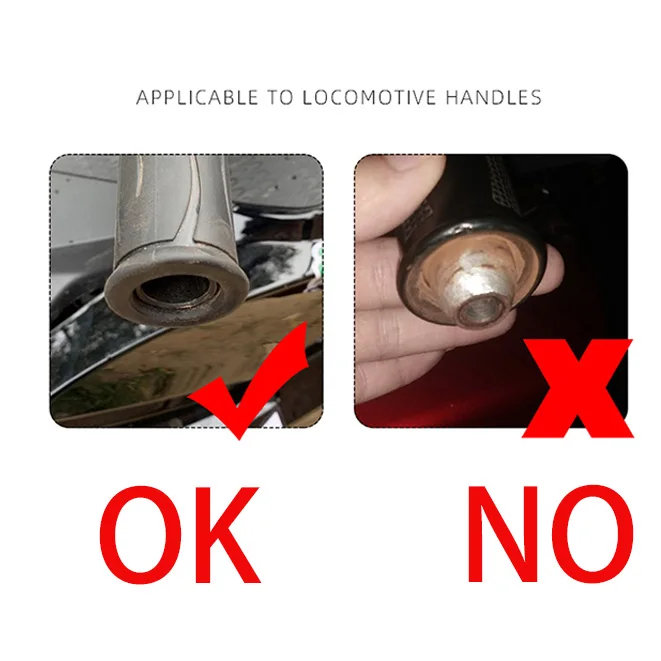

- Custom handlebars and grips.

- Enhanced lighting solutions.

- Improved tires for better traction.

Common Issues with Thundercat Models

When it comes to specific motorcycle models, enthusiasts often encounter a range of typical problems that may arise during ownership. Understanding these common challenges can aid in early detection and resolution, ultimately enhancing the riding experience. Below are some frequently reported issues that riders might face.

- Electrical Problems: Issues with the electrical system, such as faulty wiring or weak battery connections, can lead to starting difficulties or malfunctioning lights.

- Fuel System Concerns: Clogged fuel injectors or filters can result in poor engine performance and reduced fuel efficiency.

- Cooling System Failures: Overheating can occur due to coolant leaks or a malfunctioning thermostat, potentially causing severe engine damage.

- Transmission Challenges: Gear shifting difficulties or unusual noises may indicate transmission problems that require immediate attention.

- Brake Wear: Premature brake pad wear or brake fluid leaks can compromise safety and should be addressed promptly.

Regular maintenance and inspections can help mitigate these issues, ensuring a smoother ride and prolonging the lifespan of the motorcycle.

Essential Tools for Motorcycle Repairs

To maintain and fix a motorcycle effectively, having the right set of instruments is crucial. These tools not only aid in performing repairs but also enhance the overall maintenance process, ensuring a smoother ride and prolonging the lifespan of the vehicle. Whether you’re a seasoned mechanic or a novice enthusiast, a well-equipped toolkit will make all the difference.

Basic Hand Tools

- Wrenches: A variety of sizes is necessary for loosening and tightening nuts and bolts.

- Sockets: Socket sets allow for efficient work on different fasteners, particularly in tight spaces.

- Screwdrivers: Both flathead and Phillips types are essential for various applications.

- Pliers: Useful for gripping, twisting, and cutting wires or cables.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Chain Breaker Tool: Essential for maintaining and replacing the drive chain.

- Multimeter: Useful for diagnosing electrical issues and testing battery health.

- Oil Filter Wrench: Makes it easier to remove oil filters during maintenance.

Equipping yourself with these essential tools will not only simplify the maintenance process but also empower you to tackle a variety of tasks with confidence. Regular upkeep of your two-wheeler can prevent costly repairs down the line and ensure a safe riding experience.

Step-by-Step Maintenance Procedures

Regular upkeep is crucial for ensuring the longevity and optimal performance of your motorcycle. This section outlines essential tasks that should be performed periodically to keep your vehicle in excellent condition. Following these guidelines will help you identify potential issues before they become significant problems.

Essential Checks and Services

- Inspect fluid levels and top up as needed.

- Change the engine oil and replace the oil filter.

- Examine the air filter and clean or replace it if necessary.

- Check tire pressure and tread depth for safety.

- Inspect brakes for wear and functionality.

Routine Maintenance Tasks

- Wash the exterior to remove dirt and debris.

- Lubricate the chain and adjust tension as required.

- Inspect electrical components for corrosion or damage.

- Ensure all lights and indicators are functioning properly.

- Perform a thorough check of all fasteners and bolts to ensure they are secure.

Electrical System Troubleshooting Guide

This section provides a comprehensive overview of diagnosing issues related to the electrical components of your motorcycle. Understanding the electrical system is crucial for maintaining optimal performance and ensuring safe operation. This guide will assist you in identifying common problems, utilizing effective techniques, and implementing solutions.

Common Issues: Electrical problems can manifest in various ways, including difficulty starting, malfunctioning lights, and erratic instrument readings. Begin by observing any irregularities during operation, as these can offer valuable insights into underlying issues.

Initial Diagnostics: Start your troubleshooting process by checking the battery voltage with a multimeter. A healthy battery should measure around 12.6 volts when fully charged. If the voltage is low, consider recharging or replacing the battery. Next, inspect all wiring connections for signs of corrosion, fraying, or loose terminals, as these can impede electrical flow.

Testing Components: Once you’ve checked the battery and connections, focus on individual components. Use a multimeter to test fuses for continuity and replace any that are blown. Additionally, assess switches and relays by testing their functionality according to the manufacturer’s specifications. Pay particular attention to the ignition system, as failures in this area can lead to starting issues.

Final Steps: After conducting tests and making necessary repairs, retest the electrical system to confirm that all components are functioning properly. Regular maintenance, including periodic inspections and cleaning of connections, can prevent future electrical issues and extend the life of your motorcycle.

Engine Overhaul Instructions

This section provides essential guidance for disassembling, inspecting, and reassembling the engine components of a sportbike. A thorough overhaul ensures optimal performance and longevity, requiring careful attention to detail throughout the process.

Preparation and Tools Required

Before beginning the overhaul, gather the necessary tools and equipment:

- Socket set

- Torque wrench

- Feeler gauges

- Engine oil and filter

- Gasket maker or replacement gaskets

- Cleaning supplies

- Service manual for specifications

Step-by-Step Overhaul Process

- Drain Fluids: Begin by draining the engine oil and coolant to prevent spills and contamination.

- Remove Components: Detach all components attached to the engine, including the exhaust system, air intake, and electrical connections.

- Disassemble the Engine: Carefully take apart the engine, noting the order of removal for reassembly. Keep track of all bolts and parts.

- Inspect Parts: Check for wear, damage, or excessive play in components such as pistons, rings, and valves. Replace any faulty parts.

- Clean Surfaces: Thoroughly clean all mating surfaces to ensure a proper seal during reassembly.

- Reassemble the Engine: Follow the reverse order of disassembly, ensuring all parts are securely fastened to the manufacturer’s specifications.

- Refill Fluids: Refill the engine with fresh oil and coolant before starting the engine.

Brake System Inspection Techniques

Regular assessment of the braking system is crucial for ensuring safety and optimal performance. This section outlines various methods to effectively evaluate the components and functionality of the braking system. Proper inspection can identify potential issues before they escalate, promoting reliability and driver confidence.

Visual Inspection

A thorough visual examination is the first step in assessing the braking system. Look for signs of wear or damage on brake pads, discs, and lines. Ensure that all components are securely mounted and that there are no visible leaks in the hydraulic system. Checking for discoloration on brake pads can indicate overheating, which may necessitate replacement.

Functional Testing

In addition to visual checks, conducting functional tests is essential. Engage the brakes at various speeds to listen for unusual noises, such as squeaking or grinding, which may indicate worn components. Monitor the brake pedal feel; it should be firm and responsive. If the pedal feels spongy, it could signal air in the brake lines or a failing master cylinder.

Suspension Adjustments and Repairs

Proper tuning and maintenance of the suspension system are crucial for enhancing the performance and handling of your motorcycle. This section provides insights into various techniques for optimizing suspension settings and addressing common issues that may arise over time.

Understanding Suspension Components

The suspension system comprises several key elements, including forks, shock absorbers, and linkages. Each component plays a vital role in providing stability, comfort, and control. Regular inspection and adjustments to these parts can significantly impact your riding experience.

Adjusting the Suspension Settings

Begin by checking the sag settings, which determine how much the suspension compresses under the weight of the rider. This measurement is essential for achieving the desired handling characteristics. Adjust the preload on the springs to modify the sag, ensuring that the bike responds well to various road conditions.

Addressing Common Suspension Issues

Common problems include excessive bouncing, bottoming out, or a harsh ride. Inspect the forks and shock absorbers for any signs of wear or damage. Replacing worn seals or fluid can help restore optimal performance. If the issues persist, consider seeking professional assistance to diagnose and rectify underlying concerns.

Regular Maintenance Practices

To maintain the longevity and effectiveness of the suspension, adhere to a regular maintenance schedule. This includes checking fluid levels, inspecting for leaks, and cleaning components to prevent dirt and grime buildup. Proper care will ensure a smooth and enjoyable ride.

Transmission Service and Repairs

Maintaining the transmission system is crucial for optimal performance and longevity of the vehicle. This section outlines essential procedures for servicing and addressing common issues within the transmission, ensuring smooth operation and reliability. Proper care can prevent serious complications and extend the lifespan of the components involved.

Regular inspections should be conducted to identify any signs of wear or damage. Common indicators include unusual noises, difficulty shifting gears, or fluid leaks. Addressing these symptoms promptly can prevent further complications and costly repairs.

| Service Task | Frequency | Description |

|---|---|---|

| Fluid Change | Every 12,000 miles | Replace old transmission fluid to maintain optimal lubrication and cooling. |

| Filter Replacement | Every 24,000 miles | Change the transmission filter to prevent contaminants from circulating. |

| Inspection of Components | Every 6,000 miles | Check for wear and tear on gears, seals, and bearings to ensure functionality. |

| Fluid Level Check | Monthly | Ensure transmission fluid is at the appropriate level for proper operation. |

For any significant repairs or part replacements, consulting a professional is advisable to ensure accuracy and safety. Following these guidelines will contribute to the overall efficiency and performance of the transmission system.

Bodywork Restoration Tips

Restoring the outer panels of a motorcycle can significantly enhance its appearance and longevity. This process involves careful assessment, cleaning, and repair of any damages to ensure that the bodywork looks as good as new. Here are some essential tips to guide you through the restoration process.

1. Thorough Inspection: Begin with a detailed examination of the bodywork. Look for scratches, dents, or cracks that may need attention. Identifying all the imperfections will help you create a clear plan for restoration.

2. Cleaning the Surface: Before any repairs, it’s crucial to clean the surfaces thoroughly. Use a gentle detergent and soft cloth to remove dirt and grime. This step ensures that any subsequent work, such as painting or polishing, adheres properly.

3. Repairing Dents: For minor dents, consider using a heat gun to gently warm the area, followed by a suction cup dent puller. This technique can help to pop out the dent without damaging the paint.

4. Sanding and Painting: After repairs, sand the surface lightly to create a smooth finish. Once sanded, apply primer and then paint in layers, allowing adequate drying time between each coat for the best results.

5. Finishing Touches: Once the paint has dried, polish the surface to restore its shine. Applying a protective wax can also help to keep the bodywork looking pristine and guard against future damage.

Following these steps will not only rejuvenate the motorcycle’s exterior but also help in preserving its value and aesthetic appeal for years to come.

Preventative Measures for Longevity

Ensuring the durability of a motorcycle requires a proactive approach to maintenance and care. By implementing effective strategies, riders can significantly extend the life of their machines while enhancing performance and safety.

Regular Maintenance Schedule

Establishing a consistent maintenance routine is essential. Key tasks include:

- Checking and changing the oil regularly.

- Inspecting the tires for wear and proper inflation.

- Cleaning and lubricating the chain to prevent corrosion.

- Examining the brake system for optimal function.

- Replacing air filters as needed to ensure efficient airflow.

Safe Riding Practices

Adopting safe riding habits contributes to the longevity of the motorcycle. Consider the following practices:

- Avoid abrupt acceleration and deceleration.

- Maintain a safe distance from other vehicles to prevent accidents.

- Follow speed limits to reduce wear on the engine.

- Utilize smooth steering to enhance control and stability.

- Store the motorcycle in a sheltered environment to protect it from harsh weather conditions.