Comprehensive Guide to John Deere 2025R Repair Manual

The journey of maintaining machinery often leads to the necessity for comprehensive guidance. Understanding the nuances of equipment care ensures longevity and optimal performance. This section aims to provide valuable insights into common issues and their resolutions.

Every operator knows the significance of being well-prepared. Having access to structured information allows for efficient problem-solving and can significantly reduce downtime. With the right resources at hand, tackling mechanical challenges becomes a more manageable task.

In the following sections, we will delve into essential techniques, practical advice, and detailed procedures tailored to assist enthusiasts and professionals alike. Embracing this knowledge can lead to the ultimate success in machinery upkeep.

Overview of John Deere 2025R

This section provides an insight into a compact utility vehicle designed for versatility and efficiency in various agricultural and landscaping tasks. Known for its robust performance and ease of use, this machine is a preferred choice among both professionals and enthusiasts.

Key Features

- Powerful engine options for enhanced performance.

- Compact design for easy maneuverability in tight spaces.

- Variety of attachments available for different applications.

- User-friendly controls that simplify operation.

Applications

- Landscaping and gardening tasks.

- Light agricultural work, such as plowing and tilling.

- Property maintenance, including snow removal and hauling.

- General utility tasks on farms or large estates.

Common Issues with John Deere 2025R

When operating compact tractors, several typical challenges can arise, impacting performance and usability. Recognizing these common problems can help owners address them promptly and maintain optimal functionality.

One frequent concern involves the engine, which may exhibit difficulty starting or irregular performance. This can be attributed to fuel system issues, such as clogged filters or inadequate fuel supply. Regular inspection and maintenance of these components are essential for smooth operation.

Another area to watch is the hydraulic system. Users often report leaks or inconsistent pressure, which can hinder attachment functionality. Ensuring that seals are intact and hydraulic fluid levels are adequate can mitigate these issues.

Additionally, operators might experience electrical malfunctions, including battery failures or faulty wiring. Regular checks of the electrical system can prevent unexpected breakdowns and enhance reliability.

Lastly, wear and tear on tires and tracks is a common concern, particularly in varied terrains. Keeping an eye on tread wear and ensuring proper inflation can prolong the lifespan of these components and enhance traction.

Step-by-Step Repair Procedures

This section provides a structured approach to address common issues that may arise with your equipment. Following these detailed steps will help you efficiently troubleshoot and resolve problems, ensuring optimal performance and longevity.

-

Identify the Issue:

- Listen for unusual sounds.

- Check for visible leaks or wear.

- Review performance metrics for discrepancies.

-

Gather Necessary Tools:

- Wrenches and sockets.

- Screwdrivers of various types.

- Diagnostic equipment if needed.

-

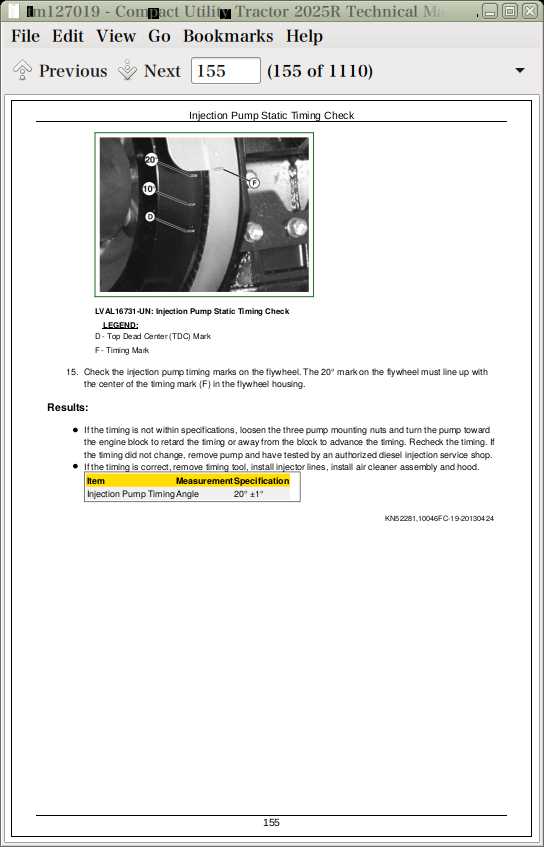

Consult Technical Documentation:

- Refer to specifications for components.

- Follow diagrams for assembly and disassembly.

-

Perform Preliminary Checks:

- Inspect fluid levels.

- Check battery connections.

- Examine electrical components for damage.

-

Execute Repairs:

- Replace worn parts as necessary.

- Tighten loose connections.

- Lubricate moving parts to reduce friction.

-

Test Functionality:

- Run the equipment at low speeds initially.

- Monitor for any recurring issues.

- Make further adjustments if needed.

-

Document Changes:

- Keep records of all repairs and parts replaced.

- Note any recommendations for future maintenance.

By adhering to these procedures, you can effectively manage the upkeep of your machinery, prolonging its lifespan and enhancing its reliability.

Essential Tools for Maintenance

Proper upkeep of your machinery is crucial for ensuring longevity and optimal performance. Having the right instruments at hand can make all the difference in executing tasks efficiently and effectively. Below is a list of indispensable tools that every owner should consider for routine care and servicing.

- Wrenches: Adjustable and socket wrenches are essential for tightening and loosening bolts and nuts.

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, will assist in handling different screws.

- Pliers: Needle-nose and locking pliers are useful for gripping, twisting, and cutting wires.

- Multimeter: This tool helps in diagnosing electrical issues by measuring voltage, current, and resistance.

- Jack Stands: For safe lifting and supporting of heavy components during maintenance tasks.

- Grease Gun: Essential for lubricating moving parts to reduce wear and tear.

Investing in quality tools not only enhances your ability to perform maintenance but also contributes to the overall efficiency and reliability of your equipment.

Understanding the Operator’s Manual

The operator’s guide serves as an essential resource for anyone looking to maximize the efficiency and longevity of their equipment. It offers invaluable insights into the proper use, maintenance, and troubleshooting of the machinery. Familiarity with this document is crucial for ensuring safety and achieving optimal performance.

Within this guide, users will find detailed instructions that outline operational procedures, recommended maintenance schedules, and troubleshooting techniques. Each section is designed to enhance the user’s understanding of the equipment, making it easier to navigate potential challenges. By adhering to the guidelines provided, operators can ensure that their machinery remains in peak condition.

Key features often include diagrams, safety warnings, and maintenance tips, which collectively contribute to a comprehensive understanding of the equipment. It is essential to read through each section thoroughly to grasp the nuances of operation and care. An informed operator is not only safer but also more capable of addressing issues proactively.

In summary, embracing the information found in the operator’s guide is vital for any user aiming to operate their equipment effectively. Regular consultation of this document can lead to improved performance and a longer lifespan for the machinery.

Tips for Routine Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Establishing a consistent maintenance routine can prevent minor issues from escalating into major repairs. Below are several practical recommendations to help you keep your machine in excellent condition.

1. Check Fluid Levels

Consistently monitor and replenish engine oil, coolant, and hydraulic fluid levels. This practice is vital for maintaining proper functionality and preventing overheating.

2. Inspect Filters

Regularly examine air and fuel filters for dirt and debris. Replacing clogged filters can enhance efficiency and prolong engine life.

3. Clean the Machine

Keep your equipment clean by removing dirt, grass, and debris after each use. This helps to avoid rust and corrosion, ensuring that components remain in good shape.

4. Examine Tires

Check tire pressure and tread regularly. Properly inflated tires not only enhance safety but also improve fuel efficiency and overall performance.

5. Grease Moving Parts

Apply lubricant to moving components as recommended in the user guidelines. This reduces friction and wear, contributing to smoother operation.

6. Schedule Regular Inspections

Plan periodic inspections by a qualified technician to identify potential problems before they become serious. Regular assessments can extend the life of your equipment.

Incorporating these tips into your routine will help maintain the efficiency and reliability of your machinery, ensuring it operates effectively for years to come.

How to Troubleshoot Electrical Problems

Tackling electrical issues in machinery can be challenging, yet systematic troubleshooting can effectively identify and resolve these problems. A structured approach will help in diagnosing the root cause of the malfunction and ensuring proper functionality.

Step-by-Step Diagnosis

Start by examining the battery and connections. Ensure that terminals are clean and tight. A weak or dead battery can lead to various electrical failures. Use a multimeter to check voltage levels; a reading below the recommended value indicates a need for replacement or recharging.

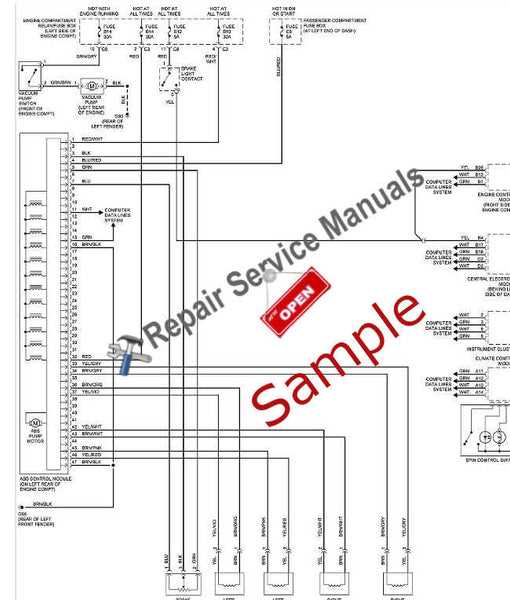

Inspecting Wiring and Components

Next, inspect all wiring and connectors for damage, corrosion, or loose connections. Frayed wires can lead to shorts, while poor connections may cause intermittent issues. If you identify damaged components, consider replacing them to restore optimal function. Additionally, refer to wiring diagrams to ensure all connections are correct and secure.

Hydraulic System Repair Guide

This section provides essential information for maintaining and troubleshooting hydraulic systems found in compact machinery. Proper understanding of these systems is crucial for ensuring optimal performance and longevity of the equipment. Addressing issues promptly can prevent minor faults from escalating into more significant problems.

Begin by familiarizing yourself with the components of the hydraulic assembly, including pumps, cylinders, hoses, and valves. Regular inspections for leaks, wear, and proper fluid levels are vital. If any irregularities are detected, it is important to address them immediately to maintain system integrity.

When troubleshooting, start with the basics. Verify fluid levels and check for contamination, as dirty or low fluid can severely impact performance. Next, examine all connections and fittings for signs of wear or leaks. Replacing damaged hoses or seals can often resolve pressure loss issues.

If the system is not responding correctly, it may be necessary to assess the pump and actuators. Listen for unusual noises, which can indicate internal wear or malfunction. Testing pressure output can also help identify faulty components that require attention.

Lastly, ensure that you follow safety protocols while working on hydraulic systems. Always relieve pressure before performing any repairs and wear appropriate protective gear. A systematic approach will facilitate effective maintenance and enhance the reliability of your machinery.

Engine Maintenance Best Practices

Maintaining an engine is crucial for ensuring its longevity and optimal performance. By adhering to best practices, operators can prevent potential issues, improve efficiency, and enhance overall reliability. Regular attention to various components not only extends the life of the engine but also supports safe operation and reduces costly repairs.

Regular Fluid Checks

One of the most essential aspects of engine upkeep is monitoring fluid levels. Oil should be checked frequently, as it lubricates critical parts and prevents wear. Always ensure that the coolant is at the appropriate level to avoid overheating. Additionally, inspecting fuel quality and cleanliness can prevent blockages and maintain efficient combustion.

Scheduled Inspections and Cleaning

Implementing a routine inspection schedule can significantly contribute to engine health. Filters should be replaced according to manufacturer recommendations, as they keep contaminants from damaging internal components. Cleaning air intakes and ensuring that exhaust systems are clear can enhance performance. Furthermore, examining belts and hoses for signs of wear can prevent unexpected failures.

Replacing Parts: A How-To

Replacing components in machinery is a vital skill that ensures optimal performance and longevity. Understanding the proper procedures not only saves time but also reduces costs associated with professional repairs. This guide provides clear steps to assist you in efficiently swapping out parts while maintaining safety and functionality.

Preparation and Safety

Before beginning any replacement task, ensure that you have the appropriate tools and safety gear. Gather items such as wrenches, screwdrivers, and pliers, and always wear gloves and goggles to protect yourself. Disconnect power sources to prevent accidents during the process.

Step-by-Step Replacement Process

Start by identifying the faulty component. Consult relevant documentation or online resources to confirm the specific part needed. Once identified, remove any surrounding components that may obstruct access. Carefully detach the malfunctioning piece by following the reverse order of installation, taking note of how everything fits together. Install the new part, ensuring all connections are secure before reassembling any removed components. Finally, test the machinery to confirm proper operation.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Following specific guidelines can significantly reduce risks and create a secure working environment. Proper preparation and awareness of potential hazards are essential for anyone involved in mechanical servicing.

Before commencing any maintenance activity, it is vital to understand the safety measures that should be in place. Below is a table outlining key precautions to observe:

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and steel-toed boots to protect against injuries. |

| Work Area Organization | Keep the workspace tidy and free from obstacles to minimize the risk of slips and falls. |

| Tool Safety | Inspect tools before use to ensure they are in good condition and suitable for the task. |

| Power Sources | Disconnect power sources and ensure equipment is off before performing any work to prevent accidental starts. |

| Lift and Support Equipment | Use proper lifting techniques and support stands to secure machinery when working underneath. |

By adhering to these safety protocols, individuals can significantly mitigate risks associated with maintenance activities, ensuring a safer and more efficient process.

Where to Find OEM Parts

Locating original equipment manufacturer (OEM) components is essential for maintaining the performance and longevity of your machinery. OEM parts are designed specifically for your equipment, ensuring optimal fit and functionality. This section will guide you on where to source these vital components.

Authorized Dealers

One of the most reliable sources for OEM components is through authorized dealers. These dealers have direct access to the manufacturer’s inventory and can provide genuine parts that meet the required standards. To find a nearby authorized dealer, visit the manufacturer’s website and use their dealer locator tool.

Online Retailers

Another convenient option is to explore various online retailers specializing in OEM parts. Websites dedicated to equipment parts often carry a wide range of components, complete with detailed descriptions and specifications. Always ensure that you verify the authenticity of the seller to avoid counterfeit products.

In conclusion, sourcing OEM components can be efficiently accomplished through authorized dealers and reputable online platforms. Utilizing these resources ensures that your equipment continues to operate at peak performance.