Toyota 5K Engine Repair Guide

Understanding the intricacies of a specific automotive system is crucial for enthusiasts and professionals alike. This section delves into essential techniques and methodologies for maintaining and enhancing the performance of a popular compact power unit. By equipping yourself with the right knowledge, you can ensure longevity and efficiency.

Whether you are a seasoned mechanic or a novice owner, having access to reliable information is invaluable. This guide outlines best practices, troubleshooting steps, and essential tips that can help you navigate through various challenges. With a focus on practical advice, you will gain insights that can streamline your workflow and optimize the functionality of your vehicle.

Emphasizing the importance of regular upkeep, this resource serves as a foundation for anyone looking to improve their skills and understanding. Each aspect of the maintenance process is presented clearly, ensuring that you can tackle any task with confidence and precision.

There are several frequent challenges that enthusiasts and mechanics encounter when dealing with this specific power unit. Understanding these common problems can aid in proactive maintenance and enhance overall performance.

Typical Problems

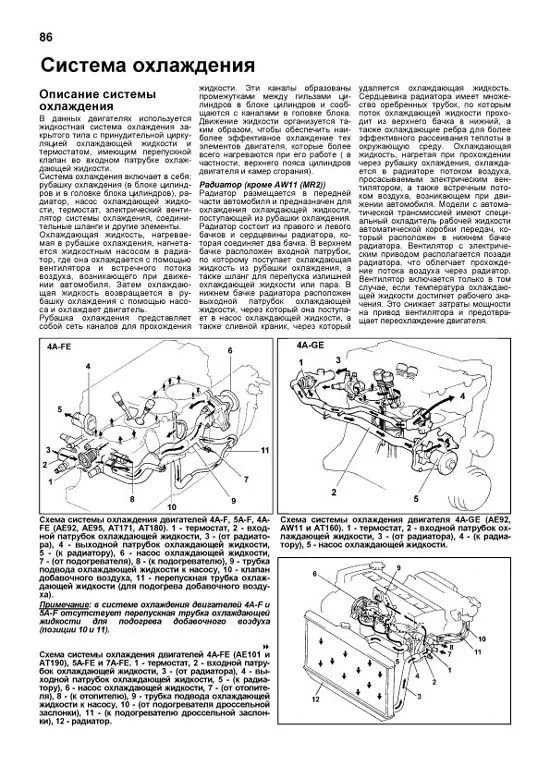

- Overheating due to insufficient cooling system efficiency.

- Excessive oil consumption resulting from worn components.

- Starting difficulties often linked to ignition system failures.

- Unusual noises indicating potential internal damage.

Preventive Measures

- Regularly check and replace cooling fluids to prevent overheating.

- Monitor oil levels and change it at recommended intervals.

- Inspect the ignition system components for wear and functionality.

- Conduct periodic assessments to detect unusual sounds early.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-equipped workspace enhances efficiency and ensures that each job can be completed with precision. The following list highlights indispensable tools that every mechanic should have on hand for effective servicing.

Firstly, a comprehensive socket set is essential for handling various fasteners. A reliable ratchet and an assortment of sockets will allow for quick adjustments and repairs. Additionally, a torque wrench is vital for ensuring that all components are tightened to the manufacturer’s specifications, preventing potential damage.

Another important tool is the set of screwdrivers, which should include both flathead and Phillips varieties. These are necessary for accessing and securing different parts throughout the system. Pliers, including needle-nose and adjustable options, are also important for gripping and manipulating components that are difficult to reach.

For more complex tasks, a diagnostic scanner can provide valuable insights into the operational status of systems, identifying issues that require attention. Moreover, having a good quality multimeter will help in testing electrical connections and components, ensuring proper functionality.

Lastly, don’t overlook the importance of safety gear. Protective gloves, goggles, and a sturdy work apron can safeguard against potential hazards while working on various tasks. Investing in high-quality tools and safety equipment will pay off in the long run, making maintenance tasks smoother and more efficient.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to routine upkeep for your vehicle, ensuring optimal performance and longevity. Following these steps will help you maintain essential components and address potential issues before they escalate.

Regular Inspection

Begin by conducting thorough inspections of critical systems. Check fluid levels, brakes, and tires for wear and tear. Make it a habit to look for any leaks or unusual noises during your assessments.

Scheduled Servicing

Adhere to a scheduled servicing plan, which includes changing oil and filters at recommended intervals. Replace worn parts promptly to prevent further damage and ensure smooth operation. Keeping records of these services will help track maintenance history effectively.

Understanding Engine Components

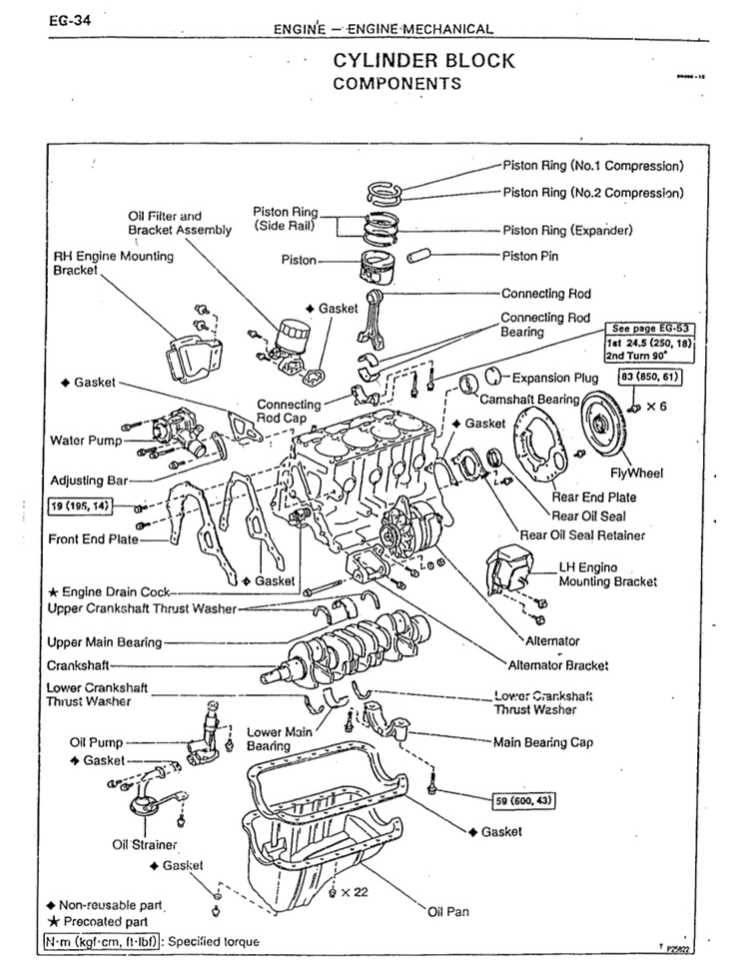

To comprehend the functionality of a vehicle’s power source, it is essential to explore the various parts that contribute to its operation. Each segment plays a pivotal role in ensuring smooth performance and efficiency, making it vital to grasp their interactions and significance.

Key Parts and Their Functions

Among the crucial elements, the *cylinder block* serves as the foundational structure, housing other essential components. It provides the necessary support and houses the pistons, which are integral for converting fuel energy into mechanical power. Additionally, the *crankshaft* is responsible for transforming the linear motion of the pistons into rotational motion, driving the wheels effectively.

Importance of Maintenance

Regular upkeep of these components is vital for longevity and optimal functioning. Neglecting even a minor part can lead to significant issues, affecting overall performance. Understanding each part’s role aids in recognizing symptoms of potential problems early, facilitating timely interventions.

Diagnostics for Engine Problems

Identifying issues in a power unit is crucial for ensuring optimal performance and longevity. This section focuses on systematic approaches to troubleshoot various complications that may arise during operation. By understanding the signs and employing effective techniques, one can diagnose underlying faults efficiently.

Common Symptoms: Various indicators can suggest malfunctions, including unusual noises, vibrations, or fluctuations in performance. Paying attention to these symptoms is the first step in the diagnostic process.

Diagnostic Tools: Utilizing specialized instruments can significantly aid in pinpointing issues. Tools such as compression testers and OBD-II scanners provide valuable data that can highlight specific areas requiring attention.

Step-by-Step Approach: Begin with a visual inspection to identify any obvious problems, such as leaks or loose connections. Follow this with testing components systematically, starting from the simplest to the most complex, ensuring each part functions correctly.

Preventive Measures: Regular maintenance and timely inspections can prevent many issues before they escalate. Keeping records of all diagnostics can also help track recurring problems and inform future maintenance decisions.

Replacing Engine Oil and Filters

Regular maintenance of lubrication fluids and filtration components is crucial for the longevity and efficiency of your vehicle. This process not only ensures smooth operation but also prevents potential damage from contaminants and degraded substances.

Gathering Necessary Tools

Before beginning the procedure, it is essential to collect the required tools and materials. You will need a suitable oil receptacle, a wrench for the drain plug, an oil filter wrench, and the appropriate lubricant along with a new filtration element. Having these items ready will streamline the process and minimize interruptions.

Steps for Oil and Filter Replacement

Start by warming up the system slightly to help the fluid drain more effectively. Next, position the receptacle under the drain plug and remove it carefully, allowing the used fluid to flow out completely. After draining, replace the drain plug and tighten it securely.

Proceed to remove the old filtration component using the wrench. Before installing the new filter, apply a small amount of fresh lubricant to its gasket to ensure a proper seal. Install the new filter and tighten it according to the manufacturer’s specifications.

Finally, pour the new lubrication fluid into the designated opening and check the level with the dipstick to ensure it is within the recommended range. This routine task not only enhances performance but also contributes to a healthier overall system.

Fuel System Troubleshooting Tips

Understanding issues within the fuel delivery system is essential for maintaining optimal performance. Various factors can affect functionality, leading to symptoms that require attention. This section provides valuable insights to help identify and resolve common problems.

Common Symptoms

- Engine stalling or misfiring

- Poor acceleration

- Unusual fuel consumption

- Difficulty starting the vehicle

Troubleshooting Steps

- Check fuel levels to ensure adequate supply.

- Inspect fuel lines for leaks or blockages.

- Examine the fuel filter and replace if necessary.

- Test the fuel pump for proper operation.

- Evaluate fuel injectors for clogs or malfunction.

Following these steps can help pinpoint and resolve issues related to the fuel supply system, ensuring reliable performance.

Electrical System Check and Repair

The electrical system is crucial for the optimal functioning of various components in any vehicle. Proper diagnosis and maintenance of this system can prevent potential issues and enhance performance. Regular checks are essential to ensure that all connections, wiring, and components are functioning as intended.

Common Issues

Electrical failures often manifest through symptoms such as dimming lights, unresponsive accessories, or intermittent starting problems. These issues can arise from faulty wiring, corroded terminals, or malfunctioning fuses. Identifying these problems early can save time and resources in the long run.

Diagnostic Steps

Begin by inspecting the battery and connections for signs of corrosion or damage. Next, use a multimeter to test voltage at various points in the system. Ensure all fuses are intact and replace any that are blown. Pay special attention to ground connections, as poor grounding can lead to numerous electrical faults.

In conclusion, maintaining the electrical system through regular checks and timely repairs is vital for the reliability and longevity of the vehicle. Consistent attention to these components will ensure smooth operation and enhance overall performance.

Performance Upgrades for 5K Engines

Enhancing the capabilities of a 5K power unit can significantly improve its responsiveness and overall driving experience. By focusing on specific modifications, enthusiasts can unlock greater potential and achieve better performance on the road.

- Intake System Improvements:

Upgrading the air intake can facilitate better airflow, leading to increased power output. Consider high-performance filters or cold air intakes.

- Exhaust Modifications:

A free-flowing exhaust system reduces back pressure, allowing the unit to expel gases more efficiently. Look for aftermarket headers and cat-back systems.

- Tuning:

Reprogramming the engine control unit (ECU) can optimize fuel delivery and ignition timing, resulting in noticeable gains in power and efficiency.

- Fuel System Upgrades:

Installing high-flow fuel injectors can ensure that the combustion process is maximized, supporting higher performance levels.

- Forced Induction:

Adding a turbocharger or supercharger can dramatically increase power output by forcing more air into the combustion chamber.

These enhancements can transform the 5K setup into a more robust and dynamic performer, catering to the demands of enthusiasts seeking improved power and efficiency.

Safety Tips During Repairs

Ensuring safety while working on machinery is paramount for both personal well-being and the longevity of the equipment. Adhering to precautionary measures can significantly reduce the risk of accidents and injuries.

1. Personal Protective Equipment: Always wear appropriate gear such as gloves, goggles, and steel-toed boots. This helps shield against potential hazards and minimizes injury risks.

2. Proper Ventilation: When performing tasks that involve chemicals or fuels, ensure the workspace is well-ventilated. Fumes can be harmful and proper airflow reduces exposure to toxic substances.

3. Use of Tools: Familiarize yourself with the tools required for the task. Using the right tool not only enhances efficiency but also decreases the likelihood of accidents caused by improper handling.

4. Disconnect Power Sources: Before starting any work, disconnect batteries or other power sources to prevent accidental activation. This is crucial for avoiding electrical shocks and other dangers.

5. Keep Workspace Organized: A tidy environment helps prevent trips and falls. Ensure all tools and materials are stored properly when not in use, creating a safer working area.

6. Follow Manufacturer Guidelines: Always refer to the specific guidelines and instructions for the equipment being serviced. These resources provide essential safety information and best practices.

By implementing these measures, you can create a safer atmosphere for yourself and others, allowing for a more efficient and secure working experience.