Comprehensive Guide to Yamaha Grizzly 125 Repair Manual

For enthusiasts and owners of all-terrain vehicles, understanding the intricacies of upkeep is essential. Proper maintenance not only enhances performance but also extends the longevity of your machine. This section aims to provide invaluable insights into the processes involved in keeping your vehicle in top shape.

In the world of off-road adventures, familiarity with technical aspects can significantly impact your experience. Whether it’s routine checks or addressing specific issues, knowing the right procedures ensures a smooth journey. This guide will delve into various techniques and tips, equipping you with the knowledge needed for effective vehicle care.

From troubleshooting common challenges to performing essential adjustments, mastering these skills will empower you to tackle any situation confidently. With a focus on clarity and precision, this resource serves as an indispensable companion for both novice and experienced riders alike.

Understanding the Yamaha Grizzly 125

This section explores the essential aspects of a popular all-terrain vehicle designed for adventure and utility. It is crucial to grasp its features, performance capabilities, and the overall user experience it offers.

Key Features

- Robust Engine: Offers reliable performance for various terrains.

- Durable Build: Constructed to withstand rough conditions.

- User-Friendly Controls: Designed for easy handling and operation.

- Comfortable Seating: Provides a pleasant ride even on long journeys.

Performance Capabilities

- Off-Road Handling: Excellent grip and maneuverability in diverse environments.

- Power Output: Sufficient strength for towing and carrying loads.

- Fuel Efficiency: Optimized for longer rides without frequent refueling.

- Maintenance Needs: Simple upkeep to ensure longevity and reliability.

Understanding these elements will enhance your appreciation of this versatile vehicle and guide you in making informed decisions regarding its use and maintenance.

Common Issues with Grizzly 125

When it comes to off-road vehicles, certain problems tend to arise more frequently than others. Understanding these typical challenges can help owners maintain their machines effectively and avoid unexpected breakdowns. This section highlights some of the most prevalent issues that enthusiasts encounter with their all-terrain vehicles.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Difficulties | Starting issues or rough idling can often be attributed to fuel or electrical problems. | Check fuel lines and connections; inspect spark plugs and battery condition. |

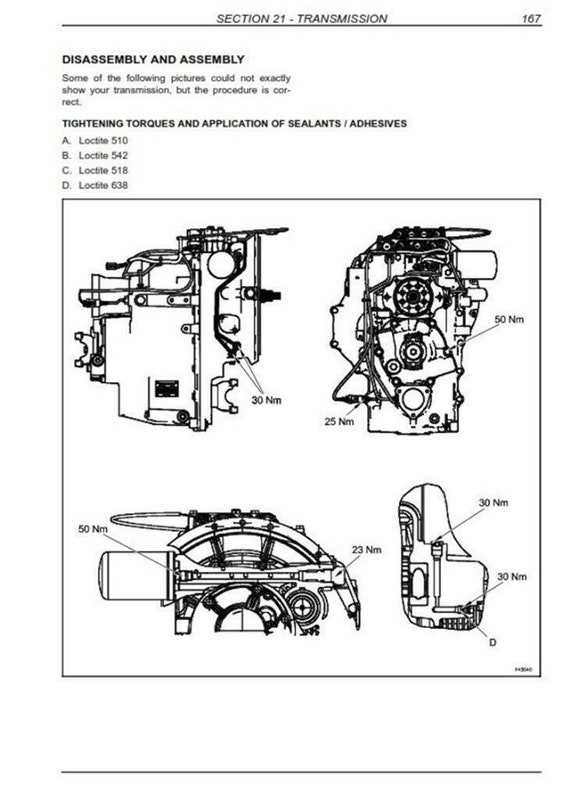

| Transmission Trouble | Shifting gears may become challenging, leading to a frustrating riding experience. | Examine the fluid levels and replace worn-out components as needed. |

| Suspension Wear | Uneven handling or excessive bouncing often indicates worn suspension parts. | Inspect shock absorbers and replace if necessary; ensure proper alignment. |

| Brake Issues | Weak or unresponsive brakes can compromise safety while riding. | Check brake pads for wear and replace; inspect fluid levels and lines. |

| Electrical Failures | Malfunctions in lighting or electronic systems can disrupt performance. | Inspect wiring for damage; replace faulty fuses or bulbs as needed. |

Essential Tools for Repairs

When tackling maintenance tasks on your vehicle, having the right set of instruments is crucial for effective and efficient work. A well-equipped toolkit not only simplifies the process but also enhances safety and precision. Understanding the necessary tools can help any enthusiast or professional navigate repairs with confidence.

First and foremost, a good quality set of wrenches is indispensable. These come in various sizes and types, enabling you to tackle different fasteners with ease. Additionally, screwdrivers–both flathead and Phillips–are essential for handling various components securely. Consider investing in a ratchet and socket set for improved torque application.

Moreover, pliers play a significant role in gripping and manipulating parts that may be hard to reach. Wire cutters and needle-nose pliers are particularly useful for electrical connections and delicate tasks. To ensure all connections are secure, a torque wrench is highly recommended for achieving the correct tightness without overdoing it.

Don’t overlook the importance of safety gear, such as gloves and goggles. Protecting yourself while working is paramount, as it prevents injuries and enhances your focus on the task at hand. With these essential instruments in your toolkit, you’ll be well-prepared for any maintenance challenge that arises.

Step-by-Step Maintenance Guide

This section aims to provide a comprehensive approach to keeping your all-terrain vehicle in optimal condition. Regular upkeep not only enhances performance but also prolongs the lifespan of your machine. Following a systematic maintenance routine will help prevent potential issues and ensure a smooth ride.

Essential Maintenance Tasks

Routine care involves several key activities that should be performed at regular intervals. Below is a table summarizing these tasks along with their recommended frequencies:

| Task | Frequency |

|---|---|

| Oil Change | Every 100 hours or 6 months |

| Air Filter Cleaning | Every 50 hours |

| Tire Inspection | Monthly |

| Brake System Check | Every 100 hours |

| Battery Maintenance | Monthly |

Step-by-Step Procedure

To effectively perform maintenance, follow these detailed steps for each task:

1. Begin with an oil change by draining the old oil, replacing the filter, and refilling with fresh lubricant.

2. For the air filter, remove it from the housing, clean it thoroughly, and reinstall it securely.

3. Inspect the tires for wear and proper inflation, adjusting as necessary.

4. Check the brake components for wear, ensuring that they are functioning properly and replace them if needed.

5. Lastly, examine the battery connections, clean any corrosion, and ensure that it is charged.

Following these guidelines will help maintain your vehicle’s performance and reliability.

Replacing the Engine Components

When it comes to maintaining optimal performance, replacing various components of the power unit is crucial. This process not only enhances efficiency but also extends the lifespan of the entire system. Proper knowledge and careful execution are essential for achieving satisfactory results.

Necessary Tools and Equipment

Before starting the replacement process, gather the following tools and equipment:

- Socket set

- Torque wrench

- Phillips and flathead screwdrivers

- Pliers

- Replacement parts

- Oil and coolant

- Clean rags

Steps to Replace Engine Components

- Preparation: Ensure the vehicle is on a flat surface. Disconnect the battery to prevent any electrical issues.

- Remove Covers: Take off any protective covers or panels to access the engine area.

- Drain Fluids: Drain oil and coolant from the engine to prevent spills during the replacement.

- Replace Components: Carefully remove the old parts. Install the new components, ensuring they fit securely and align properly.

- Reassemble: Replace covers and panels, securing them with the appropriate fasteners.

- Refill Fluids: Refill the engine with oil and coolant, following manufacturer specifications.

- Reconnect Battery: Finally, reconnect the battery and perform a systems check to ensure everything is functioning correctly.

By following these steps and using the right tools, you can effectively replace engine components, ensuring your vehicle runs smoothly and efficiently.

Electrical System Troubleshooting Tips

Troubleshooting the electrical components of an all-terrain vehicle can be a challenging yet rewarding task. Understanding the common issues and systematic approaches can help in identifying faults efficiently. This section provides valuable insights and methods to diagnose electrical problems effectively, ensuring optimal performance of your vehicle.

Here are some essential tips to consider when examining the electrical system:

| Tip | Description |

|---|---|

| Check the Battery | Ensure that the battery is charged and connections are clean. A weak or dead battery is a common cause of electrical failures. |

| Inspect Fuses | Examine the fuse box for blown fuses. Replacing a blown fuse can often resolve electrical issues quickly. |

| Test Wiring Connections | Look for loose, corroded, or damaged wires. Secure connections are crucial for proper operation. |

| Examine Switches | Check all switches for functionality. A faulty switch can interrupt the flow of electricity and lead to malfunctions. |

| Use a Multimeter | Utilize a multimeter to measure voltage, continuity, and resistance. This tool is invaluable for pinpointing issues in the electrical circuit. |

Following these tips can significantly aid in diagnosing and resolving electrical problems. By maintaining a systematic approach, you can ensure the reliability and safety of your vehicle’s electrical system.

Braking System Repair Techniques

The braking system is crucial for safety and performance, requiring regular attention and maintenance to ensure optimal functionality. Understanding the components and their interactions is essential for effective troubleshooting and restoration. This section will explore various strategies to address common issues, enhance efficiency, and prolong the lifespan of the braking assembly.

Begin by inspecting the brake pads and discs for wear and damage. If the pads appear thin or uneven, replacing them promptly is vital to maintain stopping power. Additionally, ensure that the brake fluid is at the correct level and free from contaminants. Regularly flushing and replacing the fluid can prevent moisture buildup, which can lead to corrosion and diminished performance.

Next, check the brake lines for leaks or cracks. Any signs of fluid loss should be addressed immediately, as this can compromise the entire system’s integrity. Replacing worn lines with high-quality components will help maintain consistent pressure and reliability.

Finally, evaluate the calipers for proper operation. Sticking or malfunctioning calipers can lead to uneven braking and excessive wear. Cleaning and lubricating the moving parts can restore function, while complete replacement may be necessary in severe cases. By following these techniques, users can ensure their braking systems remain responsive and effective.

Suspension System Adjustments Explained

The suspension system plays a crucial role in ensuring a smooth and controlled ride. Proper adjustments can significantly enhance performance, stability, and comfort. Understanding the intricacies of suspension tuning allows riders to tailor their vehicles to specific conditions and personal preferences, resulting in a more enjoyable experience.

Key components of the suspension system, such as springs and dampers, can be fine-tuned to achieve the desired balance between softness and firmness. Adjusting preload on the springs can influence ride height and overall handling, while modifying damping settings can help control how quickly the suspension reacts to bumps and rough terrain.

For optimal performance, it’s essential to consider factors such as rider weight, intended use, and environmental conditions. Regularly checking and adjusting these elements ensures that the suspension system functions effectively, contributing to improved safety and ride quality. With a few simple tweaks, riders can maximize the potential of their vehicle’s suspension system.

Fuel System Cleaning Procedures

Maintaining the fuel delivery system is crucial for optimal performance and longevity of any engine. Regular cleaning prevents buildup of contaminants that can hinder efficiency and lead to costly repairs. This section outlines effective methods for ensuring a clean and functional fuel system.

Preparation Steps

- Gather necessary tools: wrenches, screwdrivers, and cleaning agents.

- Ensure the work area is well-ventilated and free of flammable materials.

- Disconnect the battery to avoid electrical issues during the process.

Cleaning Process

- Remove the fuel tank and inspect for debris and rust.

- Flush the tank with a suitable cleaning solvent to eliminate residues.

- Clean the fuel lines using compressed air or a dedicated cleaning solution.

- Examine and clean the fuel filter, replacing it if necessary.

- Reassemble all components and ensure secure connections.

- Reconnect the battery and test the system for leaks before operation.

Regular maintenance of the fuel system not only enhances performance but also extends the lifespan of the engine. Following these cleaning procedures will help maintain a smooth and reliable operation.

Safety Tips During Repairs

Engaging in maintenance activities requires attention to detail and a focus on safety. Adopting the right precautions can prevent accidents and ensure a smooth process. This section outlines essential guidelines to follow while working on your vehicle.

Preparation and Environment

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure your workspace is clean and organized to minimize hazards.

- Use appropriate lighting to clearly see the components you are handling.

- Keep a first aid kit nearby in case of minor injuries.

Personal Protective Equipment

- Wear safety glasses to protect your eyes from debris.

- Use gloves to shield your hands from sharp edges and chemicals.

- Consider steel-toed boots to protect your feet from heavy objects.

- Long sleeves and pants can prevent skin contact with hot or sharp surfaces.

By following these precautions, you can create a safer environment and effectively mitigate risks while working on your machinery.

Where to Find Replacement Parts

Locating suitable components for your all-terrain vehicle can enhance its performance and longevity. Numerous avenues exist for sourcing high-quality parts, ensuring that your machine remains in optimal condition.

Online retailers are a convenient option, offering a vast selection of components with the ability to compare prices and read customer reviews. Popular e-commerce platforms frequently carry a range of aftermarket and OEM parts, making it easier to find exactly what you need.

Local dealerships also serve as valuable resources, providing not only parts but also expert advice. Engaging with professionals can help you identify the right components for your specific model, ensuring compatibility and reliability.

Additionally, specialized repair shops often stock essential parts and may even offer installation services. These establishments can be particularly helpful for those who prefer a hands-on approach to maintenance.

Lastly, online forums and community groups dedicated to enthusiasts of off-road vehicles can be excellent sources of information and recommendations. Members frequently share experiences and tips on where to find parts, which can lead you to reliable suppliers.